High-frequency joining board machine has so many advantages, naturally very popular. However, as a large machine, if you want to have a longer service life, it is naturally inseparable from regular maintenance. So how to maintain and maintain the high-frequency puzzle machine?

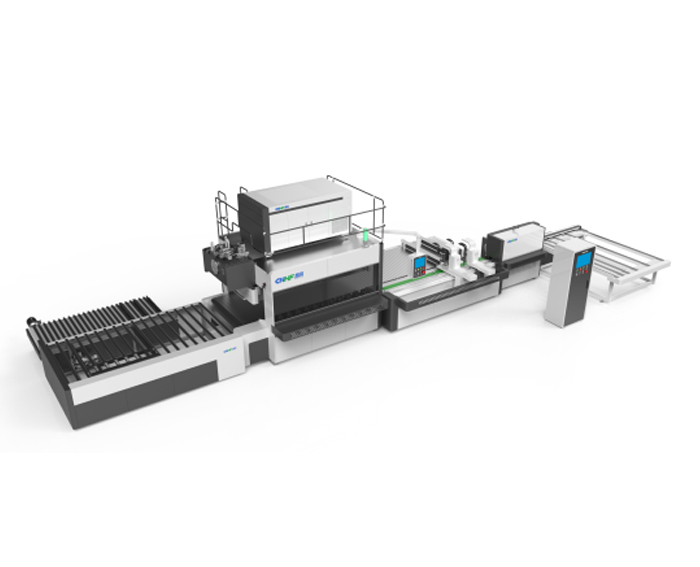

The splicing machine is mainly composed of a hydraulic system, pneumatic system, etc. It is mainly made of small-diameter logs, rotary cut wood cores, lumber, and other raw materials, after plate arrangement, coating, extrusion, heating, etc. The process is to make a full-width solid board. Let's take a look at its precautions.

1. When the splitter rotates, the suspension cylinder must be retracted to both sides of the support panel in advance.

2. It is strictly forbidden to press the clamp on the material rack and continue to rotate forward to avoid major equipment violations.

3. Clean the wooden blocks and other obstacles in the specific rotation space, so that the puzzle machine runs smoothly.

4. The gas supply of the gas circuit should be used in close cooperation with electrical appliances.

5. Adjust the one-way throttle valve to ensure that the material rack retracts the cylinder synchronously, otherwise, it will seriously affect the life of the yielding cylinder.

6. For the first jigsaw puzzle, the equipment cutting balance should be kept, and every other row should be spliced in one row. After all, pages have been spliced, the boards can be removed and the jigsaw can extend the service life of the equipment.

Adjustable high-frequency technology minimizes curing time. This means that the production efficiency is maximized while achieving a long-lasting and solid gluing effect.

Operate under reasonable operating conditions of the high-frequency joining board machine, so that it will not cause downtime due to road damage, nor will it affect safety or operation due to machine failure. It is also necessary to check the condition of the various parts of the joining board machine from time to time to achieve the longest overhaul distance. Finally, in the joining board machine we use, we must carefully maintain and maintain the joining board machine.

We found that the problem of high-frequency joining board machine should be dealt with in a timely manner, which can speed up the progress and reduce the cost of repairs, so as not to cause unnecessary trouble and loss. Don’t stop using it when using the high-frequency joining board machine. The phenomenon of de-protection is neglected by the trigger. The purpose of protection is to reduce the load, pay attention to viewing, strengthen the smooth ones, and can extend the life and improve the power effect of the operation.

The above information is provided by high frequency joining machine manufacturer.

Previous: What is the Debugging Method of the Dispenser?

Next: MT-500X Valve Core Grinding Bench Stationary Valve Grinding Machine

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used