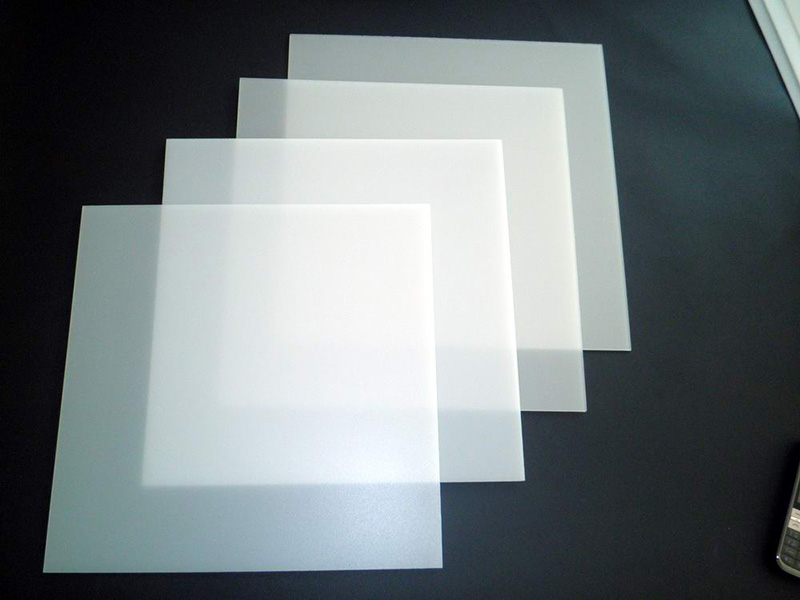

1. Low processing expenses. PMMA Diffuser plate processing is simple, may be mechanical mechanical cutting edge, and may be laser-cut or blow molding, blister and other sexy forming techniques, so at the first generation of flat-panel lamps, PMMA Diffuser Sheet is broadly used;

2. Silk display result is exceptional, with exceptional ink adsorption and adhesion. Flat-panel lamps are normally more dull, and many sellers prefer to print their logos and electric parameters on the flat-panel lamps, in addition to a number of decorative images. So if the client needs a sizable area of silk display, the first choice of class is oil;

3. China PMMA Diffuser Supplier make a test, that the transmittance of PMMA diffusion plate could reach roughly 90%. , but additionally it is troublesome to think about its ultra-high transmittance alone. It's well-known the lamp is a replica of the backlight, the airplane debris can also be required, due to the strong light, it's extremely simple to trigger bright spots and light guide plate mesh, flaws visible and so forth. Balance the transmittance and fog worth is also quite significant.

4. The impact resistance is worse than PC, but much higher than PS material.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used