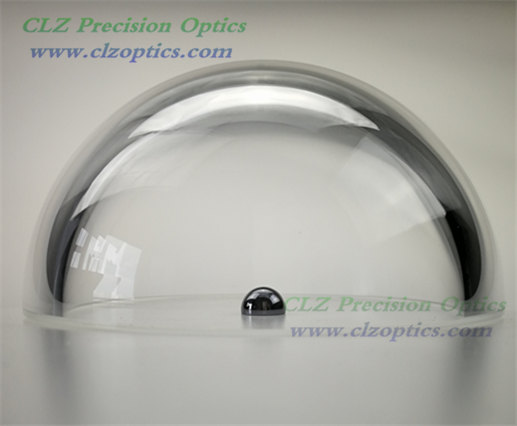

Glass Optical Dome is a glass that modifies the direction of light transmission and can modify the relative spectral dispersion of ultraviolet, visible or infrared light. As a company that offers Custom Domes, let's introduce the cleaning of optical glass.

The cleaning of optical glass is divided into pre-coating and post-coating cleaning. The processor should choose different cleaning methods according to the different pre- and post-coating contaminants.

1. Glass Optical Dome cleaning before coating

The pollutants cleaned before coating are core oil (also called grinding oil, core is also called core, core, refers to the process used to obtain the regular radius and core precision), fingerprints, dust and so on. Since the coating process is extremely strict on the cleanliness of the lens, the selection of the cleaning agent is very important. Thinking about the cleaning ability of a certain cleaning agent, I also have to think about his corrosive and other aspects.

2. Glass Optical Dome after cleaning

It usually includes pre-inking cleaning, pre-bonding cleaning and pre-assembly cleaning. The pre-bonding cleaning (joining refers to bonding two lenses with a photosensitive adhesive into a regular shape to meet the need for one-time forming, or to make a comparison. The special curvature and light transmittance process are the most demanding. The contaminants to be cleaned before joining are a mixture of dust, fingerprints, etc. It is not difficult to clean, but there is a very high requirement for the cleanliness of the lens. The cleaning method is the same as the previous two cleaning techniques.

Previous: Muffle Furnace, Tube Furnace, Lab Equipment Manufacturer

Next: Accu-Tell® Multi-Drug Fast-Dip Rapid Test Panel (Urine)

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used