Epoxy coated wire mesh is used as a support layer for hydraulic filters and air filters to support filter paper or non-woven fabrics. It is used to filter granular debris and rubber impurities from the system to ensure the cleanliness of the hydraulic and air filtration system.

Epoxy coated wire mesh is mainly woven from plain steel wire/aluminum wire/ stainless steel wire and covered with a first class epoxy resin powder by an electrostatic spraying process, making this material impervious to corrosion and acids. Epoxy coated wire mesh is generally used as an auxiliary layer for decontamination rather than galvanized wire mesh. It is ideal due to the stability of the structure and the economic situation. It is used for almost all filters.

Plain steel wire / aluminum wire / stainless steel wire, epoxy powder

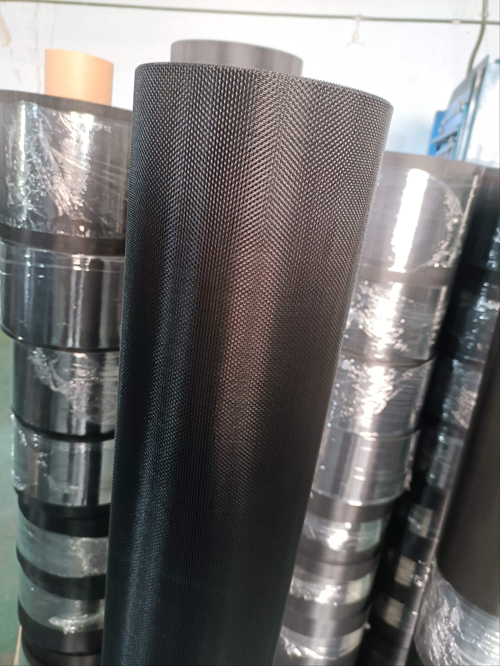

Dark gray and black epoxy coating as standard, other colors can be customized, such as gray, white and blue etc.

►Epoxy coating makes it rust and corrosion resistant

►Lightweight

►Stable mesh structure, simple pleating

►Highly compatible with different kinds of corrosive fluids

►Resilient under high temperature and pressure

►Easy to clean and tidy

Epoxy coated wire mesh is commonly used in different filtration applications as an auxiliary layer for hydraulic filters and air filters, producing a certain good pleating effect, providing maximum air flow and peak filtration.

When epoxy coated wire mesh is used as an epoxy coated filter cable mesh, it is used as a hydraulic filter as well as an air filtration auxiliary layer to support filter paper or non-woven fabric for filtering drill bits debris and rubber impurities from the system to ensure certain hydraulic system as well as air filtration system cleanliness.

Epoxy coated wire mesh is also used as an insect-proof line for windows and doors. It is widely used to resist insects such as flies, insects and bed bugs in hotels, buildings and homes.

| The Main Specifications | |||

| Mesh | Wire Diameter | Width | Length |

| 14x14 | BWG31/32 | 0.6 - 1.5 m | 100-1000LF |

| 16x14 | BWG31/32 | 0.6 - 1.5 m | 100-1000LF |

| 16x16 | BWG31/32 | 0.6 - 1.5 m | 100-1000LF |

| 18x14 | BWG31/32 | 0.6 - 1.5 m | 100-1000LF |

| 18x16 | BWG31/32 | 0.6 - 1.5 m | 100-1000LF |

| 18x18 | BWG31/32 | 0.6 - 1.5 m | 100-1000LF |

| 20x20 | BWG32/33 | 0.6 - 1.5 m | 100-1000LF |

| 22x22 | BWG32/33 | 0.6 - 1.5 m | 100-1000LF |

| 28x28 | BWG33/34 | 0.6 - 1.5 m | 100-1000LF |

| 30x30 | BWG33/34 | 0.6 - 1.5 m | 100-1000LF |

1. Good flexibility: folded mesh on a rod of 1mm radius of curvature, no fracture on the surface.

2. weather corrosion resistance: according to ASTM B117-09 salt spray test standard. Can be tested in the salty environment for 96 hours continuously and the mesh surface remains unchanged. Suitable for air filters used in harsh environments and outdoor environments.

3. Oil immersion corrosion resistance: It can be tested under different temperatures and times by various brands of hydraulic oil media around the world, and the coating surface remains unchanged. Suitable for high temperature and high pressure special hydraulic filtration products.

4. Strong adhesion: It can pass H grade pencil test, 1kg/50cm impact test, scratch test, and fatigue resistance test.

5. The edge line will not fall off after slitting and cutting.

Epoxy coated wire mesh can be directly rolled into rolls or cut into strips. We work with consumers to provide custom-cut, installation-ready epoxy-coated meshes to help simplify the building and construction process.

60 sets of fast weaving looms are set up on-site to ensure the quality of raw mesh with high precision of opening, straightness of warp and weft lines, mesh defect control and size control; epoxy powder has different brands, we usually choose industrial oil-resistant powder and civil corrosion resistant powder. The two sets of epoxy coating equipment adopt advanced manufacturing process, the coating performance is effectively improved and the coating capacity reaches 15,000 square meters/day.

We welcome any inquiries from you!

Previous: Types of Steel Pipe Fittings

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used