As one of the Thermoforming Plastic Sheet Suppliers, let's talk about the technical requirements for acrylic sheets.

1. Hardness: Hardness is one of the parameters that best reflects the production process and technology of casting acrylic sheet, and is an important part of quality control. The hardness can reflect the purity of the raw material PMMA, the weather resistance of the sheet, and the high temperature resistance. The hardness directly affects whether the sheet will shrink and bend, and whether the surface will be cracked during processing. Hardness is one of the hard and good indicators for judging the quality of acrylic sheets, and the average Dalhou hardness value is about 89 degrees.

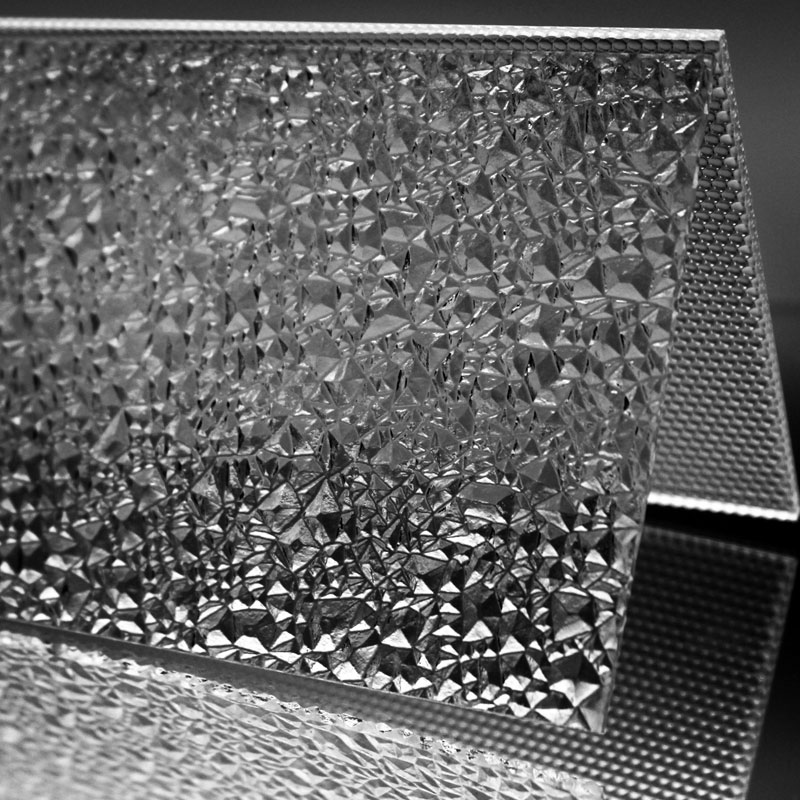

2. Transparency/Whiteness: The pure acrylic sheet is crystal clear, such as crystal, and the sheet made of recycled material can be seen from the side to see yellow or blue.

3. Thickness tolerance: The control of sheet thickness tolerance is an important manifestation of quality management and production technology. Acrylic production has an international standard ISO7823

Tolerance requirements for cast-in-place plates: tolerance = ± (0.4 + 0.1 x thickness)

Tolerance requirements for extruded plates: Tolerance = < 3 mm Thickness: ± 10 % > 3 mm Thickness: ± 5 %

Our company has Textured Acrylic Sheet For Sale. Welcome to contact us.

Previous: What Are The Benefits of EPE Foam?

Next: How to Improve the Efficiency of Heat Resistant Conveyor Belt?

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used