The dryness and moisture content of wood are an important index for evaluating wood; keeping wood dry and controlling moisture content is also an important aspect that affects the durability of wood. In this paper, the wood drying process and common drying methods are briefly introduced by the intelligent wooden joining machine manufacturer.

Wood drying process

The drying of wood is a staged process:

Initially, the surface is dry;

Then the moisture inside the wood gradually drains the surface

Surface redrying

Repeat the process

This is basically the basic principle of wood drying. Our traditional wooden building materials, construction will follow this principle.

Drying process

There are several drying techniques in the industry. All of these methods may vary depending on the type of equipment used, and may also transfer heat energy to the material being dried in various ways.

In most cases, the drying process of different types of wood is divided into:

Conductance drying method;

The use of radiation technology;

Currently, there are many different ways and methods to dry wood. However, there are several main and most commonly used wood drying methods:

Natural air drying: is the cheapest and simplest process organization method, but it is also the longest process; in addition, this method requires a lot of space.

Kiln drying: Drying lasts about a week, and defects such as cracks or uneven drying process may appear.

The infrared method is a high-quality method: fast drying speed, easy to use, low power consumption, not suitable for enclosed space types.

The vacuum drying method is the fastest and will not cause various deformations. The negative: high equipment prices and high power consumption.

Condensation drying is fast-get high-quality material at the output end, it is best for large materials.

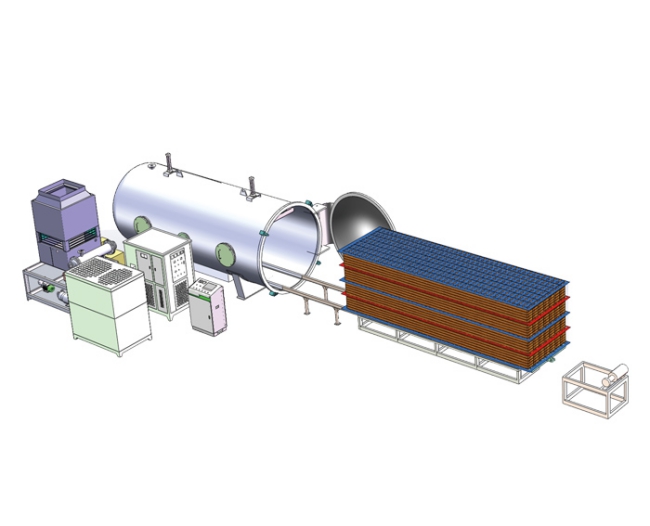

Our company's vacuum timber dryer adopts high-frequency drying technology, and the wood is heated at the same time inside and outside, heating uniformly, drying speed, short drying time, and good quality. It can maintain the natural color of the wood and at the same time aerate the wood in a vacuum environment without cracking. It is especially suitable for thick and hardwood or for secondary drying of wood.

Previous: Laser Cutting Machine Maintenance Content And Method

Next: Horizontal Type SYTW600/5-32 Top Pressure Valve Test Bench valve tester valve pressure test machine

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used