1. The High Precision Mesh Welding Machine can be welded after passing through the water. The moving parts of the welding machine should be kept lubricated frequently. The welding parts should be welded after cleaning to avoid damaging the electrodes or affecting the service life of the welding electrodes.

2. When the welded wire mesh machine is working at a temperature below zero degrees Celsius, the cooling water remaining in the cooling pipe should be blown off with compressed air after welding to avoid freezing and freezing of the water pipe and the welding transformer.

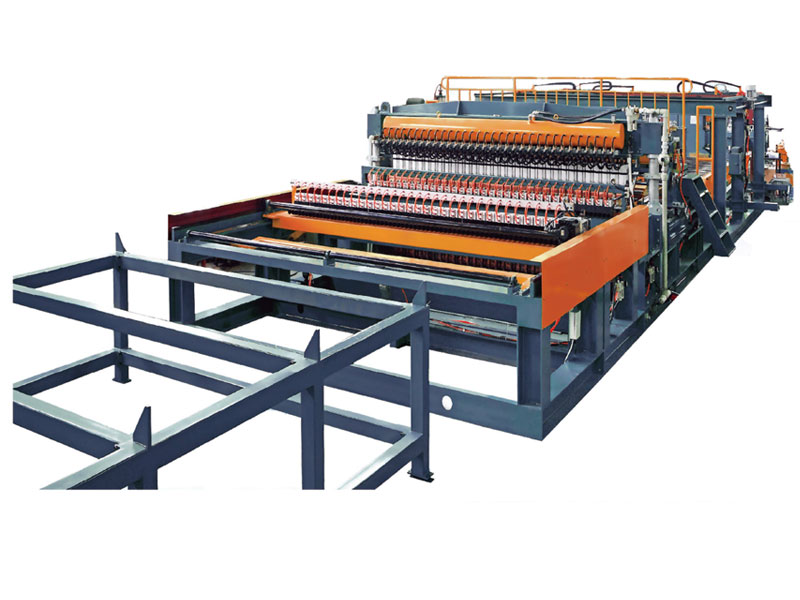

High Precision Mesh Welding Machine

3. The Automatically Mesh Welding Machine should be repaired and maintained after the power is cut off. The operator should wear canvas gloves and work around to avoid burns.

4, welded wire mesh machine can not be damp, to prevent leakage. Before using the welder for a long time, check whether the insulation resistance is qualified. Use 500V megohmmeter to test the insulation resistance between the incoming power supply line and the outer casing of the welder to be no less than 2.5 megohms.

5. There should be no corrosive gas, chemical deposits and corrosive, explosive and flammable media that seriously affect the insulation performance of the welder.

6. The welding net machine should work strictly according to the rated load duration, and no overload is allowed.

7. The water separation filter of the air source treatment device must be drained frequently. The water level of the accumulated water should not exceed the warning line. Otherwise, the compressed air containing water will enter the oil mister and the solenoid valve cylinder, causing the cylinder of the solenoid valve to wear faster and even fail to work normally.

Previous: SY-880 Automatic Dimsum Sumai Shaomai Making Machine sumai machine

Next: Copeland Air-Cooled Low Temperature Condensing Unit (-5~5 ℃, -20~-10 ℃, -35~-20 ℃)

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used