Flotation is one of the most important processes in the beneficiation process and is widely used. According to statistics, more than 90% of non-ferrous metal minerals are treated by flotation. In addition, the flotation process is also used for beneficiation of ferrous metals, precious metals and non-metallic minerals. The flotation slurry transportation of flotation is achieved by using a centrifugal slurry pump, and the centrifugal slurry pump will reduce the performance, flow rate, head, and efficiency of the pump when conveying gas-containing slurry, and exacerbate the over-flow parts Wear and tear, and even cause the pump to malfunction. The key to solving the above problems lies in the choice of foam pump structure and foam coefficient. At present, different types of centrifugal foam pumps have been developed at home and abroad, with mixed results, and the selection of the foam coefficient has not been unified. Based on this, I summarized the advantages and disadvantages of foam pumps with different structures to provide a reference for the selection design of the flotation process.

1 Foth pulp pump types and characteristics

At present, the centrifugal pumps are used in the foam conveying pumps at home and abroad. In the pump type structure, the following pump structures have been mainly used.

1.1 Ordinary horizontal centrifugal slurry pump

Ordinary horizontal centrifugal slurry pumps generally use the AH series and the ZJ series. The AH series slurry pumps are foreign technologies introduced in the mid-1980s; the ZJ series are in the late 1980s, and are limited by the Coal Science and Technology Research Institute. The slurry pump series developed and designed by the company. Because these two types of slurry pumps are widely used in the ore slurry transportation of the ore dressing plant, the technology is relatively mature. Therefore, when the flotation foam pump was selected at home and abroad, this ordinary centrifugal slurry pump was used instead of the foam pump. For the transportation of foam pulp. Because these pump structures are not specifically designed for conveying flotation foam, in actual operation, the phenomenon that the conveying capacity fails to meet the design requirements, and the slurry pool overflows.

The use of ordinary centrifugal slurry pumps as foam pumps has the following disadvantages: ① In order to transport slurry with a large air volume fraction, a larger size slurry pump must be used. In some stations with large air volume fractions, even It is also difficult to increase the pump size; ② It must be operated in the area to the left of the high efficiency point, and the slurry pump is operated at a small flow rate; ③ The efficiency is significantly reduced when conveying foam-containing slurry. The decrease in efficiency means an increase in energy consumption.

Although ordinary horizontal slurry pumps have many shortcomings that are not suitable for flotation foam slurry transportation, due to their advantages such as simple structure, mature technology, low price, and a large number of manufacturers, they are still in use at present in major mines.

1.2 Vertical foam slurry pump

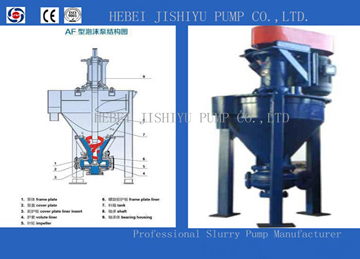

Because the ordinary horizontal foam pump is often used to transport foamed ore slurry, it often has difficulty in conveying the ore slurry and the overflow phenomenon of the ore slurry pool. In the 1990s, the domestic introduction of AF series vertical foam pumps for flotation foam transfer, as shown in Figure 3. Compared with the ordinary centrifugal slurry pump, the vertical foam pump has the following advantages: using a tapered feed box with a tangential feed port, the foam slurry enters the tapered feed box through the tangential feed port, and spirally enters the cone The bottom of the shaped feed box, while entering spirally, is equivalent to increasing the contact time of the foam pulp with air, which is beneficial to the precipitation of gas in the pulp; the use of a semi-open impeller increases the air bubble conveying capacity.

Due to its structural limitations, vertical foam pumps have the following obvious disadvantages: ① The main shaft cantilever is long and the delivery head is limited by the critical speed; ② The use of a tapered feed bucket results in a large area; The horizontal pump is poor and prone to vibration; ④ The price is higher than the horizontal pump; ⑤ The overflow part of the pump is in the lower part of the conical barrel, which makes it very difficult to maintain.

Adopting vertical foam pump as the flotation foam conveying, the conveying effect is better than the ordinary horizontal centrifugal slurry pump, but the effect is not obvious. On the contrary, due to its outstanding shortcomings and problems in actual production applications, vertical foam pumps have been gradually phased out in domestic mines, and have now been gradually replaced by ordinary horizontal centrifugal slurry pumps.

1.3 Specially designed horizontal centrifugal foam pump

At the beginning of the 21st century, there were beneficiation plants outsourcing foreign professional foam pumps in China, and their use effect was remarkable. This foam pump uses a specially designed horizontal centrifugal foam pump, which solves the difficulty of foaming by ordinary centrifugal slurry pumps from the hydrodynamic model and fundamentally solves the problem of foam slurry transportation.

This froth pump has the following advantages: ① large suction size, inlet size designed according to the flow of gas-containing slurry; ② semi-open metal impeller with spiral compression function , Retains the characteristics of centrifugal impeller, has a higher conveying head, and has the advantages of spiral blades, suitable for conveying high gas content pulp; ③ can be conveyed stably, and will not cause unstable flow due to interrupted flow; Higher energy consumption than other types of slurry pumps.

From the current foreign beneficiation plants, the use of specially designed foam pumps has become the first choice for flotation foam slurry delivery, but there has not been a large-scale application in China. The main reason is that foam pumps with special structural designs are produced by only a few manufacturers in China, while foreign equipment is expensive.

This specially designed foam pump is used in the underflow of thickeners in foreign mines. The spiral blades perform a certain degree of shear on the high-concentration slurry, reducing the viscosity of the slurry and improving the transportability of the slurry Sex.

We are a slurry pump, FGD pump, sump pump and froth pulp pump supplier in China, Our products are mainly used for transport of solid particles with a strong abrasive, high-concentration slurry.

For more information on pumps, please click here.

Previous: Europe Smart RFID Hotel Door Lock System

Next: General Fire and Explosion-Proof Technology in High-Risk and Explosive Industry

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used