As a CNC Machining Parts Manufacturer, let's share with you the precautions for non-standard parts processing of grinding.

1. The abrasive grain size for grinding should be from coarse to fine and replaced sequentially. When replacing the abrasive, the grinding marks of the previous process should be completely removed, and the grinding should be carried out until the current grinding marks can be seen. The punching thimble is very important to prevent the phenomenon of "relief".

2. The same lap can only use the same size of abrasive. Before changing the particle size, the workpiece, such as CNC Turning Parts, must be thoroughly cleaned to prevent the coarser abrasive grains or other dirt from being carried to the next process. Scratch of the abrasive surface.

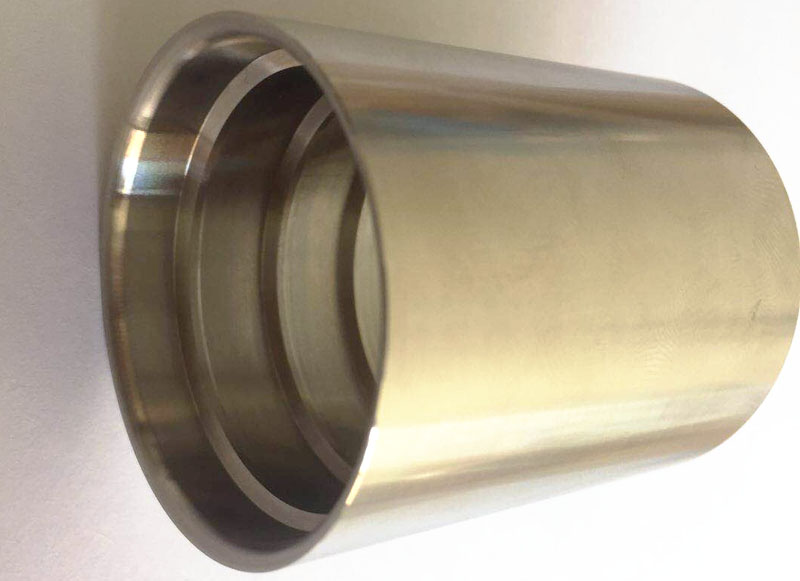

CNC Turning Parts

3. Whenever the next particle size is converted, it should be ground at an angle of 30-45° with the last grinding direction. If there is a deep scar, it is not possible to grind only the local position. Otherwise, the local position will be pitted, and the whole pit should be completely trimmed to remove the pit. Uniform grinding is required for stations that are easy to grind and that are not easy to grind.

Our company specializes in providing Metal CNC Machining Services. If you need it, please feel free to contact us.

Previous: High Pressure Swivel Joint

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used