As a Fused Silica Windows Manufacturer, let's talk about how the optical lens should be installed. If the installation method is not correct during installation, the optical lens will be contaminated. If you have followed the previous operating procedures. If a large number of lenses need to be installed and removed, the fixture must be designed to complete the task. Special fixing devices reduce the number of contacts with the lens. This can reduce the risk of lens contamination or damage.

The same as the lens is not installed properly, the laser system will not work properly. The laser system may be damaged. All CO2 laser lenses must be mounted in one direction. The high reflector of the output mirror reacts to the cavity. Its high penetration confronts the joint. When the lens is mounted back, the laser does not produce laser light or generate a low energy laser. The convex surface of the final focusing lens reacts to The second surface of the lens is concave or planar. This includes work. If it is reversed, the focus and working distance will change significantly. In the cutting application, the cutting joint becomes larger and the cutting speed becomes slower. Mirror Is the third normal lens, installation is also important. Of course, you can easily distinguish between reflectors and reflectors. Apparently the coating is facing the laser.

Typically, the manufacturer marks the edges to help identify the surface. The mark is usually an arrow pointing to one side. Each lens manufacturer has a lens marking system. In general, the arrows are high and reversed for mirror and output mirrors. , the arrow points toward the concave or flat surface. Sometimes there is the meaning of the reminder tag on the lens tag.

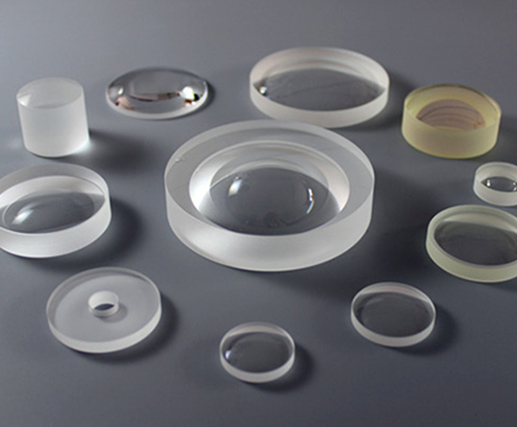

Our company also offers Meniscus Lenses. Welcome to contact us.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used