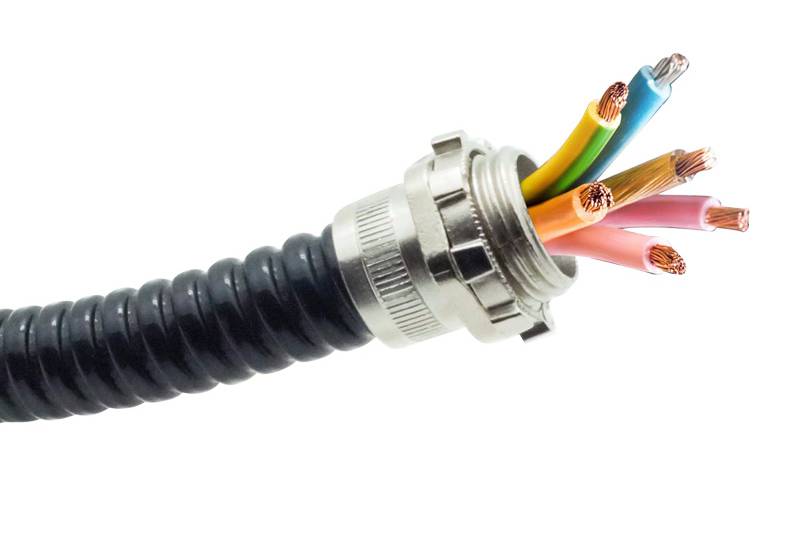

As an Aluminum Flexible Metal Conduit Supplier, let us introduce the installation method for everyone.

Although Metallic Flexible Conduit can be stretched and stretched, it can break quickly and reduce its service life if it is not installed in the correct position.

The hose can be installed horizontally or vertically or diagonally. The ideal condition is vertical installation, and should be avoided near the wheel. If necessary, a baffle can be added.

The Metallic Flexible Conduit can generally be divided into three lengths: the first is the compression length, which is the length when the hose is compressed to the limit position; the second is the installation length, which is halfway between the maximum displacements. The length of the hose; the third is the length of the stretch, the length at which the hose is stretched to its maximum limit.

The Metallic Flexible Conduit should be installed with the hose in the middle position, the so-called installation length. In this position, the hose can have two moving directions when subjected to axial load. Otherwise, if it can only move in one direction, it will affect the strength of Metallic Flexible Conduit and reduce the service life.

1. When using metal hose, please use metal hose with loose flange at one end for easy installation.

2. The surface of the metal hose should be protected during the welding work at the construction site to prevent welding slag and arc ignition from burning the metal hose.

3. It is strictly forbidden to twist the installation of Metallic Flexible Conduit.

4. It should not be bent along the root of Metallic Flexible Conduit. There should be no dead bends.

5. The medium to be passed shall not be corrosive to the corrugated pipe material, and the chloride ion content in the medium shall be ≤25PPM.

6. Strict installation and installation of the correct installation method.

7. It is strictly forbidden to damage the flange sealing surface by mechanical damage.

Previous: Significant Improvements to USB 3.1

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used