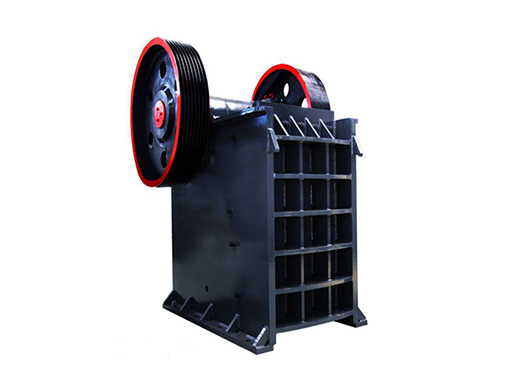

How to make jaw crusher play an important role in stone production line

Jaw crusher is an important general in the mine crusher production line. It is the most core equipment in the entire production line and controls the development of the entire production line. So how can we make the jaw crusher indispensable in the stone production line? The equipment plays an important role and creates greater value. The editor of Ding Bo Heavy Industry (custom Jaw crusher manufacturers) will explain to everyone.

Jaw crusher occupies an important position in the stone production line. If you want to make the jaw crusher work better, avoid the following abnormal situations during operation and use, so as not to damage the machine and extend its service life.

First, the equipment should be maintained regularly. In the process of using a jaw crusher, because the cost of the machine is relatively serious, the screws of the internal parts of the machine or the screws that fix the machine often become loose. This requires regular tightening of the machine's screws.

Secondly, the machine oil should be changed regularly. After the machine is used for a period of time, the internal lubricant will reduce the lubrication effect, and the debris that falls during the operation of the machine will deposit in the lubricant, which will also increase the wear of the machine. Therefore, when the lubricant is used for a period of time, it must be replaced in time. After replacement, clean the inside thoroughly with kerosene to avoid residue. In this way, the machine is less prone to wear.

Third, the internal temperature of the machine is too high. Jaw crusher generates a lot of heat due to friction during use. Failure to dissipate heat in a timely manner and build up heat in the machine can damage the machine. For example, the central axis of a machine can deform due to high temperatures and damage it when it is crushed. Therefore, when using the crusher, you must always pay attention to the internal temperature. If the temperature of the machine is too high, stop working in time and use it when the temperature drops.

Fourth, pick out iron when adding raw materials. If there is iron in the raw material, the jaw of the jaw crusher will be damaged, making the machine unusable.

Fifth, if the particle size of the added material is not uniform. When too much raw material enters the machine, it can be damaged due to overload.

When the jaw crusher works, it is necessary to observe the content of the manual and strictly maintain the machine, which can not only reduce energy consumption but also increase output.

We are a construction sand making equipment supplier, which has professional technical force and perfect production capacity. Our impact crusher, sand making machine widely applied in mining, road building, bridge building and so on.

Please click here for more product information.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used