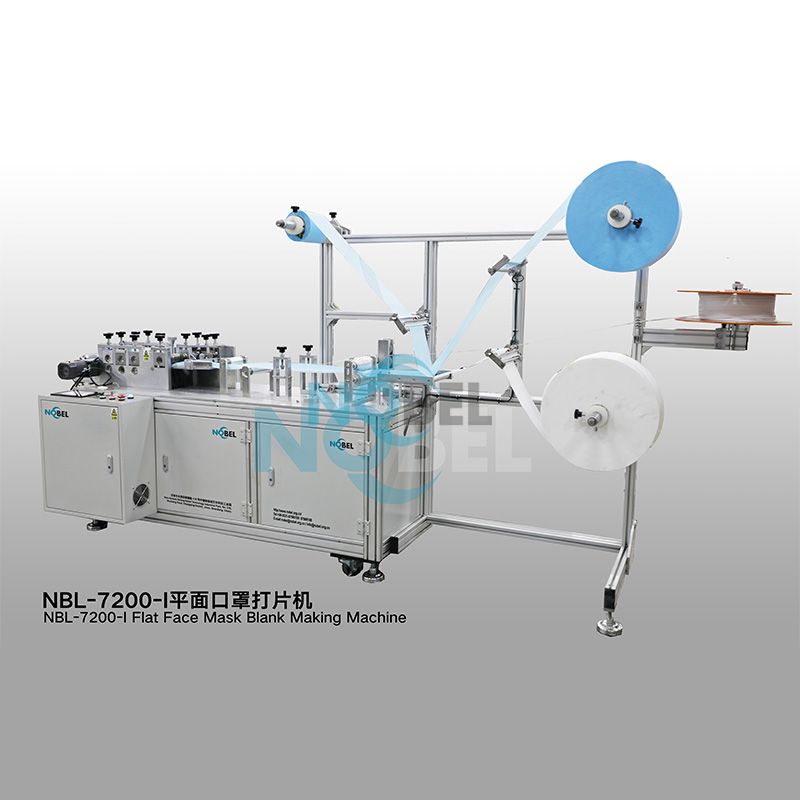

NBL-7200-I Flat Face Mask Blank Making Machine medical mask production line Mask Making Machine Manufacturer

Company Profile

Nobel (Shandong) science and Technology Industry Co., Ltd. was founded in 2013 with a registered capital of 11 million yuan (RMB). Its business scope covers the research and development, production and sales of medical devices and software products. It is a well-known overall solution provider in China's medical device industry. With excellent R & D strength, the products involve 7 series and more than 60 kinds of products, including in vitro diagnostic medical devices, full-automatic Newcastle disease detection system, full-automatic tumor cell rapid analysis and screening system, full-automatic mask production line and supporting detection system.

Equipment Introduction

NBL-7200-I flat mask blanking machine is an automatic equipment for welding the outer layer (non-woven fabric), middle layer (white filter solvent spray non-woven fabric), inner layer(skin-friendly non-woven fabric) and nose clip strips of disposable masks into mask blanks (specifications: 175 ± 5mm * 95 ± 5mm).

The equipment consists of four parts: feeding of raw materials, lamination of the mask, feeding of the nose bridge, and ultrasonic welding and cutting. It automatically completes non-woven fabrics, meltblown cloth, feeding of the nose bridge, long edge ultrasonic sealing, automatic folding, short edge ultrasonic edge banding and cutting functions.

Flat Mask Machine Technical Parameter

Equipment size: about 3600mm * 880mm

Equipment capacity: less than 260 pieces / minute

Equipment yield: 99%

Machine power: about 3kW

Voltage: 220VAC 50 / 60Hz (please specify voltage requirements when ordering)

Machine pressure: ≥0.5-0.6MPa

Nobel Mask Machine Advantages

1. Stable machine performance, continuous adjustable production speed, high production efficiency, up to 260 pieces per minute, with automatic counting function, convenient and accurate counting, high raw material utilization rate, simple and convenient operation and adjustment, high degree of automation, effective Reduce labor costs.

2. Cloth folding adopts insert-type folding device, which is easy and fast to debug and calibrate.

3. Adopting large diameter welding wheel, welding is reliable and beautiful, effectively reducing product deformation.

4. Using aluminum alloy frame, strong and beautiful.

5. The tension setting can be performed to adjust the tension of the non woven material, thereby effectively ensuring the beauty and flatness of the finished product.

6. Adopt independent nose strip conveying group for easy adjustment and maintenance.

7. Using a first class well-known brand ultrasonic transducer, 20K international frequency standard, the output is more powerful and stable, effectively ensuring the welding quality of the product.

8. The PLC is used to automatically control the whole machine to reduce the operation difficulty of the user.

Flat face mask blank making machine can automatically completes non-woven fabrics, meltblown cloth, feeding of the nose bridge, long edge ultrasonic sealing, automatic folding, short edge ultrasonic edge banding and cutting functions.

For more information or news about the face mask making machine,please click here.

https://www.nobelindustrial.com/product-mask-blank-making-machine.html

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used