Slurry pump common troubleshooting solutions (below)

Six, leakage at the packin

For example, if the shaft and the filling box have different axes, the main reason is that the machining error is large and the installation is incorrect. Care should be taken to check that the installation is correct after installation. If the sealing water ring is seriously worn, a new water ring needs to be replaced. If the sealed water pipe is blocked, the sealing water cannot enter the middle of the packing, causing the packing to wear quickly, resulting in leakage. The blocked water pipe should be dredged to keep the sealed water clean.

Seven, slurry pump heating

Cause: Bearing damage; slurry pump rolling bearing or bracket cover clearance is too small; pump shaft is bent or the two shafts are not concentric; the tape is too tight; lack of oil or oil quality is bad; the balance hole on the impeller is blocked, the impeller is out of balance, increase Big thrust to one side. Remedy: Replace the bearing; remove the rear cover, install a gasket between the bracket and the bearing housing; investigate the pump shaft or adjust the concentricity of the two shafts; properly adjust the tightness of the tape; add clean butter, butter accounts for the bearing About 60% of the inner gap; remove the blockage in the balance hole.

Eight, supporting power motor overheating

The reason for the power supply: the centrifugal slurry pumps voltage is high or low, the power supply three-phase voltage is asymmetrical, the winding will be overheated; the phase loss operation, the experience shows that the agricultural motor is burned more than 85% due to the lack of phase operation, the motor should be dealt with Install a phase loss protection device.

Reasons for the pump: The power is not matched, the small horse-drawn carriage, the motor is overloaded for a long time, the motor temperature is too high; the motor that starts too frequently, the quota is short or intermittent, the motor works continuously. The number of starts should be limited, and the thermal protection should be properly selected and used according to the calibration quota on the motor.

The reason of the motor itself: the connection error, the stator winding has phase-to-phase short circuit, inter-turn short circuit or local grounding. If the ventilation system fails, check whether the fan is damaged, whether the rotation direction is correct, and whether the slurry pump vent hole is blocked.

Reasons for the horizontal slurry pumps working environment: The motor winding is wet or dust, oil, etc. are attached to the winding, and the ambient temperature is too high.

Nine, bearing heat

There are five main reasons: 1. The cold water is not turned on or the cooling water tank is blocked. The cooling water function should be turned on or the cooling water channel should be dredged. 2, equipment lubrication is not good. The amount of lubricant should be adjusted according to the instructions. 3. The lubricating oil is not clean and there are impurities in the oil. The bearings should be cleaned and the lubricant replaced. 4. The thrust bearing is in the wrong direction. Adjust the thrust bearing direction for the inlet pressure. 5. The bearing air outlet is blocked, which causes the hot air in the bearing housing to be discharged, which makes the temperature of the equipment rise. The air outlet should be cleaned up.

Ten, short bearing life

There are four main reasons: 1. The motor shaft and the pump shaft are asymmetrical or non-parallel. The motor shaft or pump shaft should be adjusted and the shaft should be replaced if the shaft is deformed or bent. 2. The bearing assembly is unreasonable. Reinstall the bearing and shaft, or replace the bearing. 3. There is friction in the pump or the impeller is out of balance. The friction should be eliminated or the new impeller replaced. 4. The lubrication is not good. Too little or too much impurities will result in a short bearing life. The bearing should be taken out and cleaned before use.

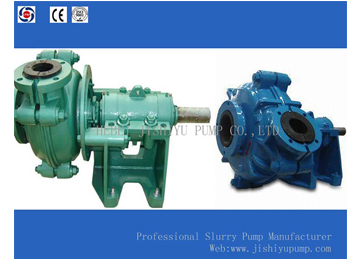

The products such as slurry pump, multistage pump, sewage pump are widely used in metallurgy, mining, petrochemical, coal, electricity and so on. Welcome to choose us!

For more information on pumps, please click here.

Previous: How to repair and refurbish wooden furniture?

Next: aluminium-alloy pipe

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used