Wood has undergone many processes before becoming furniture. Due to the nature of the wood, solid wood furniture will crack and deform. Making wood more stable is the core of the puzzle.

According to the size requirements of product parts, primary wood processing materials are selected. High-Frequency Joining Machine manufacturer shares with you.

Cutting material is cutting the wood to the required size. According to the size requirements, cut the specified size width.

This is also an important part of the selection of materials. The unqualified materials will be selected in the first step because it will directly affect the quality and effect of the product.

After the wood has been processed in length and width, it must be processed in thickness. This completes the first step of the preliminary selection, and then the pre-processed wood is cut by a multi-piece saw. In order to ensure the seamless stitching of the board when we are paneling, we use a full-automatic edge trimming saw. In order to ensure the beauty of the board, we must strictly compare the color and texture of each part to ensure the quality of the product.

In order to avoid this problem as much as possible, it is necessary to pay attention to the process of "panning" the wood, that is, cut the whole board into several pieces, and then splice them together. This can eliminate the defective parts of the wood and reduce the wood. Coefficient of expansion and contraction to improve stability.

In order to create high-quality wooden products, there are strict requirements for the process of the puzzle.

1. consistent thickness

Planing and trimming of wood are the basic requirements to ensure the quality of the jigsaw, and the process indicators must be strictly followed to ensure that the thickness of the veneer is consistent.

2. Consistent colors

Chromatic aberration is the most intuitive factor that leads to the quality of the jigsaw. Strict selection of veneers with roughly the same color and texture is used for splicing. Apply evenly when gluing to prevent gaps between veneers.

3. Orderly pressure

When using a jigsaw to perform the jigsaw, first add auxiliary pressure to flatten the board, and then press down to tighten; when dismantling, first remove the pressure, and then release the auxiliary pressure to prevent the just pressed jigsaw plate from cracking without being completely shaped.

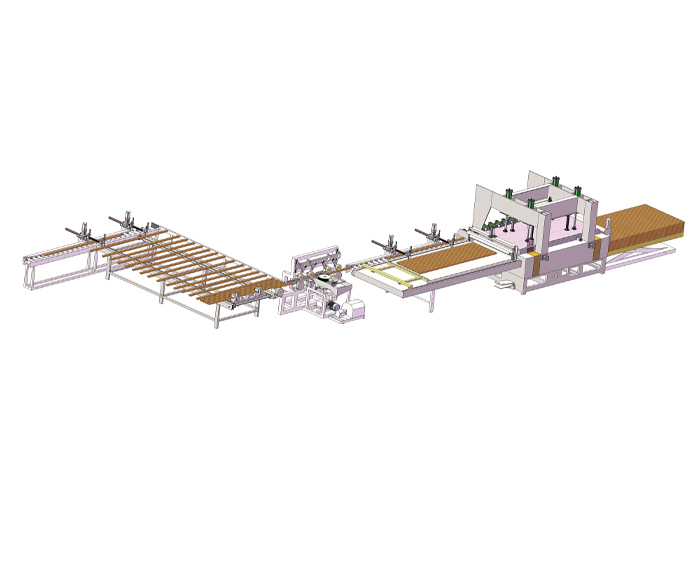

High frequency Joining Machine, using a high-frequency hot press, two-dimensional pressure, can be used for panel, wood edge sealing, L-shaped door set line combination, door core panel splicing. It can solve the problems of heating speed, heating efficiency, automatic production, environmental protection and safety in the process of panel assembly more efficiently.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used