With the increasing variety of screen printing materials, the variety of screen printing materials has greatly increased. Generally speaking, silkscreen materials were originally borrowed from other industries, and later some other types of materials were developed with the need for silk screen printing.

But while a wide variety of nonmetallic materials are already used in the silk-screen printing industry, such as silk, nylon mesh, and polyester mesh, they are still not sufficient for all silk-screen printing needs. For example, for dye printing or porcelain ink printing screen material must withstand ink and solvent long-term erosion, the screen needs to be recycled. In order to meet the needs of the silk screen printing, people are badly in need of a long life, stability, good screen, and stainless steel wire mesh was born.

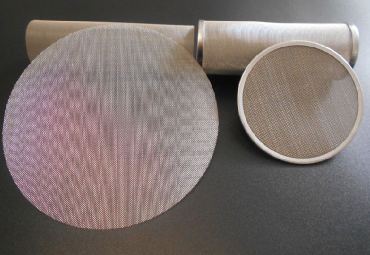

Stainless Steel Wire Mesh

Stainless steel wire mesh because its wire diameter is very consistent and can be very thin, so it can be printed the most delicate patterns. The mesh of stainless steel wire mesh (mesh) is also very consistent, also larger than the mesh of other wire mesh materials, and stainless steel wire mesh is not as easy to absorb ink non-stainless steel wire mesh, its wire does not absorb ink or solvent, so you can get a relatively flat ink film layer. It has many advantages: the frequent replacement of the template will not damage the stainless steel wire mesh; Ink also easily through the stainless steel wire mesh; Especially suitable for the use of porcelain ink, glass ink, plate copper ink, and dye ink printing occasions; Can be used for more delicate work; Stainless steel wire mesh can get a thicker ink film layer; Better rigidity, accurate overprinting in printing; Can be used for mechanical automation, semi-automation or manual printing. In the past, due to the stainless steel wire mesh is not easy to stretch and expensive reasons, generally only used to make the small screens, but more and more used in medium and large screens. Although it is more expensive and less flexible, its consistency and infinite availability reduce the overall cost. And correct drawing and printing techniques can compensate for poor elasticity.

There are two types of weaving of stainless steel screens for screen printing, plain weave, and twist weave. plain weaving is more commonly used, and twist weaving is mostly used for very delicate operations. Plain weaving is the overlapping of single warp and weft, while twist weaving is the overlapping of double warp and weft. The meshes produced by the two weaving methods are square in shape. The skein method produces thicker screens.

Like other wire meshes, stainless steel wire meshes are classified by mesh size (number of wire mesh). Use only square meshes instead of rectangular meshes in screen printing. Square meshes have the same number of meshes and the same large mesh size in the length and width directions. The number of meshes per inch or centimeter is calculated by the number of all meshes from any one network cable to a distance of 1 inch. For example, No. 80 wire mesh should have 80X80 meshes per square inch, that is, 6400 meshes; No. 300 stainless steel wire mesh should have 300X300 meshes per square inch, that is, 90,000 consistent meshes.

Stainless steel wire mesh is generally marked with the words "Number 80" or "80X80", "Number 165" or "165X165". Stainless steel wire mesh types typically range from 80 lines / inch (31 lines / cm) to 635 lines / inch (250 lines / cm). However, rougher stainless steel screens are also available on the market. The lower the number of lines, the larger the mesh; conversely, the higher the number of lines, the smaller the mesh. In wire mesh, the diameter of a wire is in inches or millimeters.

The choice of silkscreen depends on the reproduction of the work, the type of ink and the condition of the printing surface. You can buy wire cloth of any size above 1 square foot (0.09 square meters), and it can be from 36 inches (91 cm) to about 79 inches (200.7 cm) in width and unlimited in length.

Stainless steel screen printing has a wide range of applications, not only for general paper printing but also for a wide range of adaptability. For example ceramics, glass, printed circuit boards, etc. Depending on the texture of the printed matter, it is not the same when printing. Although each series has an inseparable internal connection, due to the different physical properties of the printed matter (that is, different chemical and physical properties), each has its own particularity. For investors, screen printing is definitely an excellent project. At the same time, due to the huge market demand, it is undoubtedly a huge opportunity.

Previous: 100% cotton combed shirt fabric

Next: Cotton Kids Wholesale Hooded Poncho baby hooded Beach Towel YKT7058

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used