https://www.chinayidahpmc.com/redispersible-polymer-powder-manufacturers.html

In the vast landscape of construction materials, redispersible polymer powders (RDP) have emerged as a cornerstone for modern adhesive formulations. These versatile powders, derived from synthetic polymers, offer unparalleled performance in various construction applications, from tile adhesives and waterproofing membranes to exterior insulation and finish systems (EIFS). As the demand for sustainable, high-performance building solutions grows, redispersible polymer powder manufacturers play a pivotal role in innovating and refining these materials. This blog delves into the intricacies of the industry, highlighting key aspects of RDP production, applications, market trends, and, importantly, introducing one of China's leading manufacturers, Hebei Yida Cellulose Co., Ltd.

At the heart of every redispersible polymer powder lies a sophisticated manufacturing process. These powders are typically produced through emulsion polymerization, where monomers such as vinyl acetate, styrene, or ethylene are polymerized in an aqueous medium under controlled conditions. The resulting emulsion is then spray-dried to form fine, free-flowing particles that can be easily redispersed in water to regain their original polymeric properties. This redispersibility is crucial, enabling the formation of strong, flexible bonds when mixed with various binders, fillers, and additives to create adhesives and coatings.

Manufacturers must meticulously control the polymerization process to ensure consistent particle size distribution, which directly impacts the powder's redispersibility and, ultimately, the performance of the final adhesive. Factors like temperature, pH, and shear rate during emulsification, as well as the choice of surfactants and emulsifiers, all contribute to the quality of the RDP. Table 1 below illustrates some common types of redispersible polymer powders and their primary applications.

| Type of Redispersible Polymer Powder | Primary Monomer | Applications |

|---|---|---|

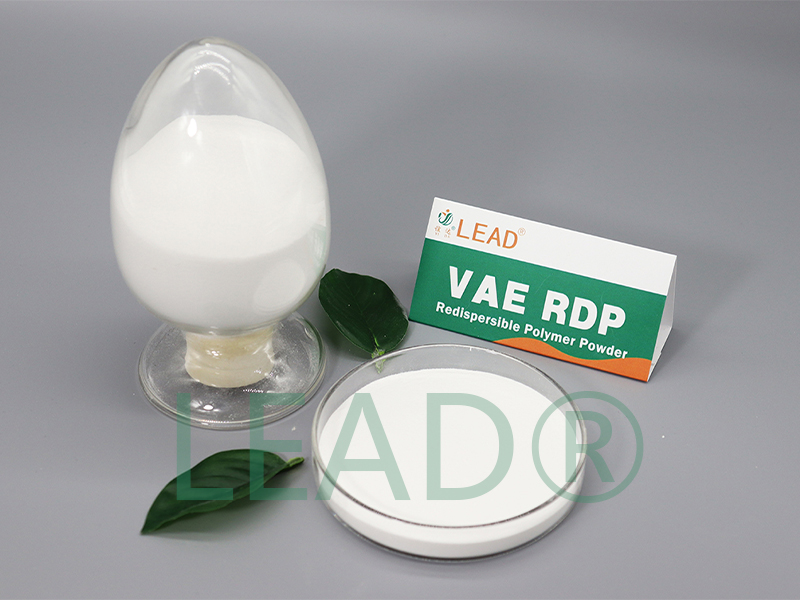

| Vinyl Acetate-Ethylene (VAE) | Vinyl Acetate, Ethylene | Tile adhesives, waterproofing, paints |

| Vinyl Acetate-Vinyl Chloride (PVAc/PVC) | Vinyl Acetate, Vinyl Chloride | Textile coatings, paper treatments |

| Styrene-Acrylic (SA) | Styrene, Acrylic Acid | Exterior insulation, flexible mortars |

| Polyvinyl Alcohol (PVOH) | Vinyl Alcohol | Wood adhesives, sealants |

The global redispersible polymer powder market is experiencing significant growth, driven by the increasing demand for eco-friendly building materials and the expansion of the construction industry, particularly in emerging economies. Manufacturers are responding to this demand by developing new formulations that enhance durability, reduce environmental impact, and improve workability.

One notable trend is the integration of biobased monomers into RPPs, aiming to reduce carbon footprints and promote circular economy principles. For instance, using lactic acid derived from renewable sources to produce polylactic acid (PLA)-based polymers offers a sustainable alternative to traditional petroleum-based monomers. Additionally, advancements in nanotechnology are enabling the creation of RPPs with enhanced mechanical properties and improved adhesion to a wider range of surfaces.

Despite the promising outlook, redispersible polymer powder manufacturers face several challenges. Fluctuations in raw material prices, particularly those of petroleum-based feedstocks, can significantly impact production costs. Regulatory compliance, especially regarding volatile organic compound (VOC) emissions and hazardous waste management, is another critical area requiring ongoing attention.

However, these challenges also present opportunities for innovation. Manufacturers are exploring alternative raw materials, such as biobased and recycled polymers, to mitigate cost volatility and environmental concerns. Collaboration with research institutions and government bodies to develop industry-specific guidelines and standards can further facilitate sustainable practices and market growth.

Amidst this dynamic landscape, Hebei Yida Cellulose Co., Ltd. stands out as a leading redispersible polymer powder manufacturer in China. With years of experience and a deep commitment to quality and innovation, Yida has established itself as a trusted partner in the construction industry. The company's state-of-the-art manufacturing facilities employ advanced production technologies to ensure consistent product quality and meet international standards.

Yida's portfolio of RDP encompasses a wide range of formulations tailored to meet specific application needs. From standard VAE-based powders for general-purpose adhesives to specialized styrene-acrylic blends for high-performance exterior applications, Yida offers solutions that balance cost-effectiveness with superior performance. Moreover, the company's focus on sustainability, evident in its ongoing efforts to reduce environmental impact and explore biobased alternatives, aligns with the global shift towards greener construction practices.

In conclusion, redispersible polymer powder manufacturers are at the forefront of driving innovation and sustainability in the construction industry. By continuously refining production processes, exploring new materials, and addressing market challenges, these manufacturers are shaping the future of adhesive technologies. Hebei Yida Cellulose Co., Ltd., with its robust portfolio, commitment to quality, and forward-thinking approach, exemplifies the best of what this industry can achieve. As the demand for high-performance, eco-friendly building solutions continues to rise, Yida is poised to remain a key player in advancing the use of redispersible polymer powders worldwide.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used