Steel grating, a durable and versatile construction material, is crafted from flat steel bars arranged in a specific pattern and welded under high pressure. This process involves cutting, incision, and overlocking to meet customer specifications. Known for its open grid structure, steel grating consists of bearing bars aligned in one direction and connected to perpendicular cross bars or bent connecting bars. This design supports heavy loads with minimal weight, making it ideal for industrial and commercial applications. Widely used in various industrial settings, steel grating provides durable platforms for floors, mezzanines, stair treads, fencing, trench covers, and maintenance platforms. Its durability and strength are crucial for areas with heavy machinery, such as factories, workshops, and boiler rooms.

Steel grating is a robust structure made from steel bars welded or locked together at junctions, forming a grid-like pattern.The main components of steel grating include bearing bars, which are vertically positioned at regular intervals to carry loads, and cross bars, which are horizontally fixed to stabilize the structure. There are two main manufacturing processes: Welded Steel Grating, where bars are welded at intersections for stability and durability, and Pressure-Locked Grating, where bars are mechanically locked without welding under high pressure.

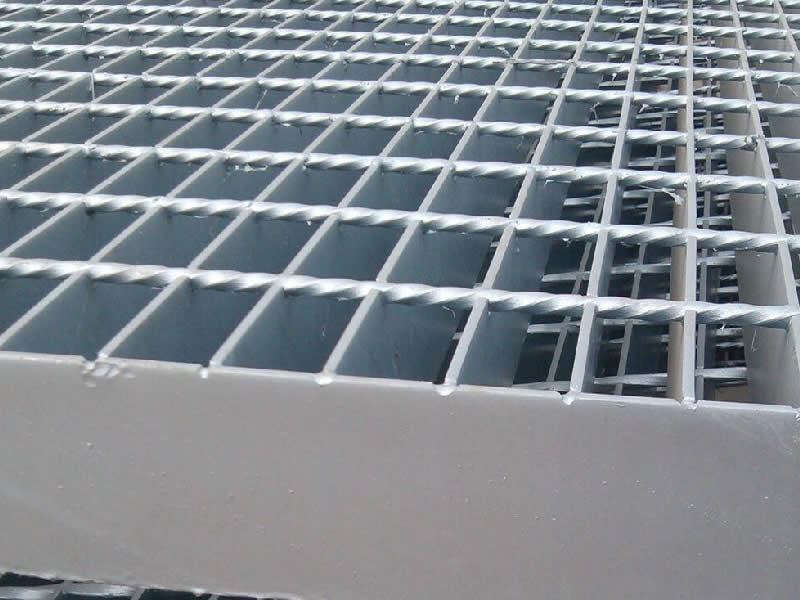

Flat Bar Steel Grating

Flat Bar Steel Grating Serrated Steel Grating

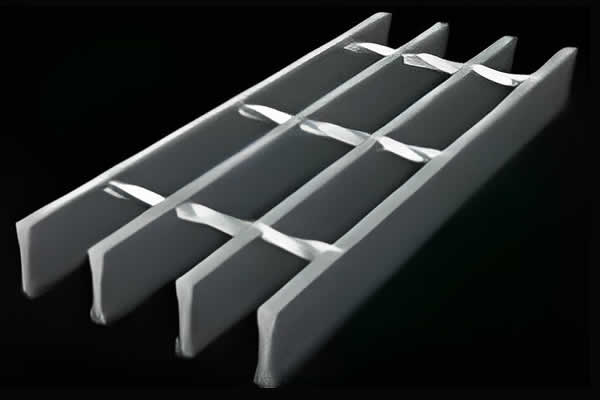

Serrated Steel Grating I Type Steel Grating

I Type Steel Grating

Carbon Steel Grating: Widely used for its strength and cost-effectiveness, often galvanized to resist corrosion.

Stainless Steel Grating: Offers excellent corrosion resistance and is ideal for harsh chemical or sanitary environments.

Aluminum Grating: Lightweight and corrosion-resistant, suitable for marine and architectural applications.

Galvanized Steel Grating: Carbon steel coated with zinc to enhance durability and corrosion resistance.

Fiberglass Grating: Non-metallic option that is lightweight, non-conductive, and resistant to chemicals.

Steel grating is available in various bearing bar types, each designed to meet specific needs in different environments:

Smooth Flat Steel Bar Grating

Features: Flat, even surface.

Applications: Ideal for stable movement in areas such as walkways and equipment pathways.

Serrated Toothed Bar Steel Grating

Features: Equipped with a serrated, tooth-like pattern.

Applications: Provides enhanced slip resistance, suitable for wet or oily environments.

Smooth I Bar Steel Grating

Features: Characterized by an I-shaped cross-section.

Applications: Used where load-bearing capacity and material efficiency are critical, offering reduced weight and high strength.

Serrated I Bar Steel Grating

Features: I-shaped profile with a serrated surface.

Applications: Delivers structural efficiency and slip resistance, ideal for areas requiring strength and safety in challenging conditions.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used