Huansi Wire Mesh Products Co., Ltd. offers a comprehensive range of crimped wire mesh products, with diverse types, specifications, and applications. Our manufacturing process involves pre-crimping wires before weaving, ensuring a stable and uniform mesh structure. This method enhances the mesh’s structural integrity and provides various crimping styles for efficiency, functionality, and visual appeal. Ideal for numerous applications, such as filtration, security, and architectural decoration, our crimped wire mesh delivers consistent performance and a refined aesthetic.

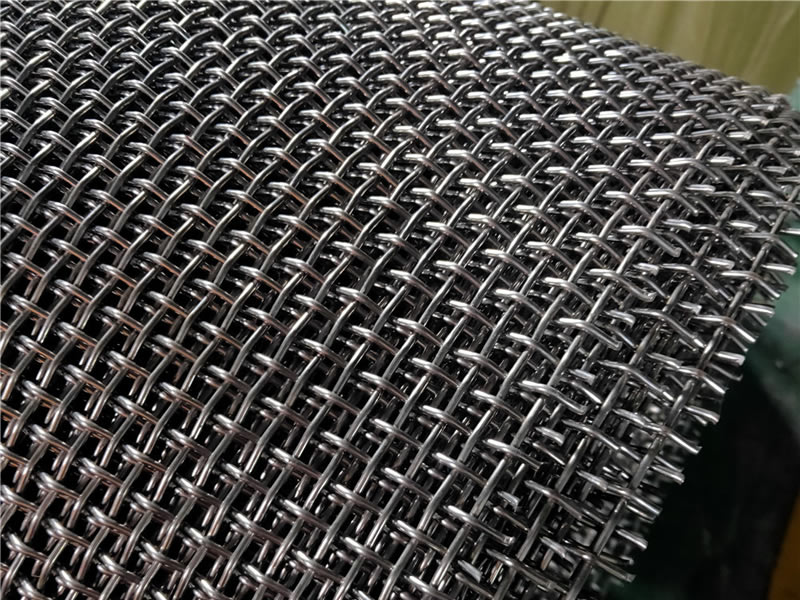

Crimped wire mesh is crafted from various materials like carbon iron, galvanized, stainless steel, or copper wires. Each wire is pre-crimped using a mold before being woven together. The range of materials, wire diameters, and weave patterns make crimped wire mesh suitable for diverse industrial applications. With its durable construction and versatility, It’s well-suited for filtration, sieving, and architectural projects, among other uses. Lock-Crimped Inter-Crimped or Multi-Crimped Double-Crimped or Plain Weave Flat Top Crimped Crimped Woven Mesh

Crimped Woven Mesh Crimped Wire Screen

Crimped Wire Screen Crimped Mesh for Vibrating Screens

Crimped Mesh for Vibrating ScreensTypes

This is a refinement of the pre-crimp technique. The crimping of both warp and shute wires is done to ‘lock’ them together at their intersection points, ensuring no wire movement. This method provides a secure and stable mesh structure, ideal for applications needing enhanced rigidity and stability.

This technique is an enhancement of the basic pre-crimp weave, where warp and shute wires feature extra crimps or corrugations between intersection points. It is particularly useful when weaving large openings with fine wires. The additional crimps secure the wires and add rigidity and accuracy to the mesh.

The most common type of wire cloth, this weave pattern crimping occurs due to the over-under pattern as warp and shute wires pass over each other. The resulting corrugations create a secure structure, suitable for various filtration and screening applications.

Flat top crimped mesh has wires that form a crimp-free surface on one side. The smooth, flattened design minimizes wire wear while providing excellent rigidity, making it suitable for architectural use and screening applications that require a smoother surface.

Previous: Black Wire Cloth

Next: Epoxy coated wire mesh

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used