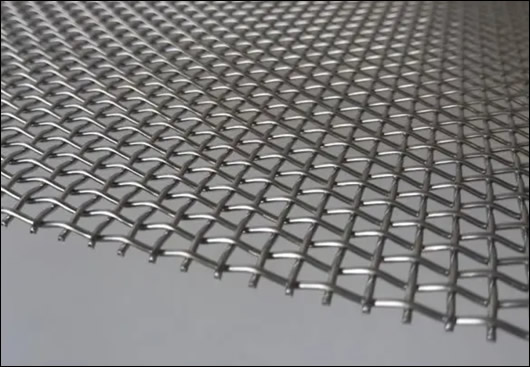

Stainless Steel Filter Wire Mesh Screens: Versatile tools essential for filtration, separation, and protection across multiple industries. They excel in water filtration, air purification, automotive, aerospace, hydraulic systems, pharmaceutical, and chemical sectors. Their durability under high pressures makes them ideal for demanding filtration tasks.

Stainless Steel Filter Wire Mesh Screens are indispensable in numerous industries, renowned for their exceptional durability, corrosion resistance, and high-temperature tolerance. Crafted from premium stainless steel types such as 304 and 316, these screens offer excellent corrosion resistance and are suitable for a wide array of applications including general industrial use, marine environments, and pharmaceutical manufacturing. Available in a variety of mesh counts from coarse to ultra-fine, and in multiple shapes and sizes, they can handle temperatures up to 800°C and meet stringent industry standards such as ASTM and ISO. Commonly utilized in water treatment, chemical processing, food and beverage production, and environmental protection, these screens ensure precise filtration and separation with high efficiency, low pressure drop, and long service life. Their adaptability to extreme environments and ability to be configured to specific operational requirements make them essential for processes requiring meticulous particle separation and fluid management.

Types of Stainless Steel

Type 316L Stainless Steel

Duplex Stainless Steel

Hastelloy

Low carbon content (maximum 0.03%) reduces carbide precipitation during welding.

Enhanced weldability and corrosion resistance.

Combines austenitic and ferritic stainless steel properties.

High strength and excellent resistance to stress corrosion cracking.

Nickel-molybdenum alloys with exceptional corrosion resistance in severe environments.

Composition and Properties

Applications

Contains approximately 16% chromium, 10% nickel, and 2% molybdenum.

Provides superior corrosion resistance, especially against chlorides and industrial solvents.

Suitable for temperatures up to 800°C (1472°F).

Marine environments, chemical processing, pharmaceutical equipment.

Composition and Properties

Applications

Contains approximately 18% chromium and 8% nickel.

Offers good corrosion resistance and excellent formability.

Suitable for temperatures up to 870°C (1600°F).

General industrial use, food processing, and architectural applications.

Type 304 Stainless Steel

Type 316 Stainless Steel

Other Stainless Steel Alloys

mining and mineral processing: screens and filters ore and minerals

Standard Wire Diameters

Fine Wires: 0.001 inches (0.025 mm) to 0.005 inches (0.127 mm) for high mesh counts.

Medium Wires: 0.005 inches (0.127 mm) to 0.01 inches (0.254 mm) for general-purpose meshes.

Thick Wires: 0.01 inches (0.254 mm) to 0.02 inches (0.50 mm) for heavy-duty applications.

Ranges from 0.001 inches (0.025 mm) to 0.02 inches (0.50 mm).

Impact on Mesh Properties

Filtration Accuracy: Thinner wires enable finer mesh counts for filtering smaller particles.

Mechanical Strength: Thicker wires provide increased durability and resistance to wear.

https://stainlesssteelwiremesh.mystrikingly.com/

https://stainlesssteelwiremesh7.wordpress.com/

https://mesh652.wixsite.com/wetter-stainless-ste

https://penzu.com/public/7b53ac2ca55bb10b

https://stainlesssteelwiremesh.jimdosite.com/

https://wetter-stainless-steel-wire-mesh-factory.ucraft.ai/

https://stainlesssteelwiremesh.weebly.com/

https://670485df191b7.site123.me/

https://substack.com/home/post/p-150544116

https://stainlesssteelwiremesh.hashnode.dev/wire-mesh-screen-stainless-steel-brass-nickel-galvanized-various-metal-wires-wire-mesh-products-for-various-purposes

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used