Die casting is a critical manufacturing process for producing intricate metal parts with high precision and durability. At Topwell Moulding, we specialize in creating high-quality die casting molds that meet the stringent demands of various industries, including automotive, electronics, and consumer goods. Our expertise ensures that every mold we manufacture offers superior performance, long-lasting durability, and exceptional accuracy.

Die casting molds play a pivotal role in the production of complex metal components. These molds must be designed with extreme accuracy to ensure that the final products meet exact specifications. Whether it's producing components for automotive engines or housing for electronic devices, precision is crucial in achieving a flawless outcome.

At Topwell Moulding, we use advanced CNC machining and cutting-edge design software to ensure that every mold is crafted with meticulous detail. Our focus on precision results in:

Consistent quality: Each part produced is identical, ensuring uniformity and reliability in mass production.

High efficiency: Accurate molds reduce material waste and manufacturing errors, streamlining the production process.

Superior fit and finish: Die casting molds designed with precision yield parts with smooth surfaces and fine details, eliminating the need for extensive post-production work.

The longevity of die casting molds is critical for maintaining production efficiency and reducing downtime. Molds subjected to repeated casting cycles must withstand high temperatures and intense pressure, making durability essential.

Topwell Moulding ensures that our molds are built to last by:

Using premium-grade materials: Our molds are made from robust alloys that resist wear and corrosion, ensuring extended life even under rigorous production conditions.

Rigorous testing and quality control: Every mold undergoes thorough testing to ensure it can withstand the mechanical stress and thermal cycling of the die casting process.

Custom solutions: We offer tailored mold designs that meet the specific needs of your industry, optimizing durability for high-volume production runs.

Experienced Team: Our engineers bring years of experience in die casting mold design and manufacturing, ensuring top-tier solutions for any project.

Advanced Technology: We leverage the latest technology and equipment to produce molds with precision, speed, and efficiency.

Industry Expertise: We serve a wide range of industries, including automotive, aerospace, and consumer electronics, providing specialized solutions that meet industry-specific requirements.

Customer-Centric Approach: At Topwell Moulding, we work closely with our clients to develop customized mold designs that align with their production goals.

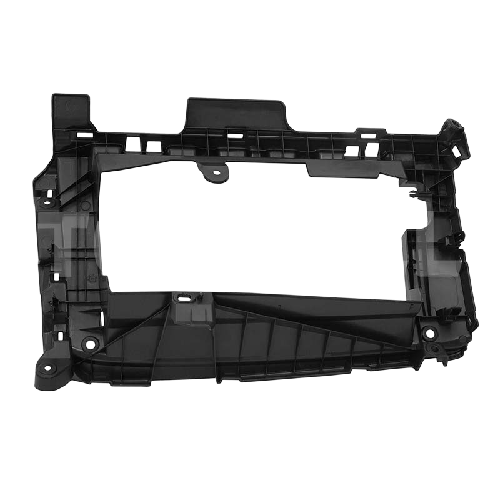

Die casting molds are indispensable in industries that require the production of durable metal parts with tight tolerances and complex geometries. Some common applications include:

Automotive components: Engine blocks, transmission housings, and heat sinks.

Electronics: Housings for devices, connectors, and intricate components.

Consumer goods: Handles, locks, and decorative metal fittings.

Die casting molds are essential for manufacturing high-quality metal parts with precision and durability. At Topwell Moulding, we are committed to delivering molds that meet the highest industry standards, ensuring your production processes run smoothly and efficiently. With a focus on precision engineering and long-lasting durability, our die casting molds are the ideal solution for your manufacturing needs.

Explore our full range of die casting mold solutions at Topwellmoulding.com and contact us to discuss how we can support your next project.

Previous: 3D Fireworks Glasses: Enhancing Your Visual Experience with Spectacular Effects

Next: Securing Your Load: The Essential Role of Tie Down Straps in Transportation and Beyond

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used