ABOUT YMX FILTER

YMX FILTER MANUFACTURING CO., LTD is a custom fabricator and manufacturer of series of metal filters and sieve equipment products.

Our factory is based in the home town of the mesh industry, Anping, Hebei province, China. Since the year 1998, we have noticed the need of the mesh filters and have set our aim as a leader manufacturer of the wire filter products. For more than 20 years’ experience, we have accumulated technique and manufacturing experiences. And now we are serving customers from a wide range of industries from all over the world.

YXM FILTERS is known as a customer-focused metal screen company that is willing to do whatever it takes to achieve total customer satisfaction. Fast turnaround times are our specialty – we understand the importance of keeping your projects on schedule, and we make every effort to deliver our products as quickly and efficiently as possible.

If you are interested in our products, please click here to visit our website.

WHAT WE MAKE?

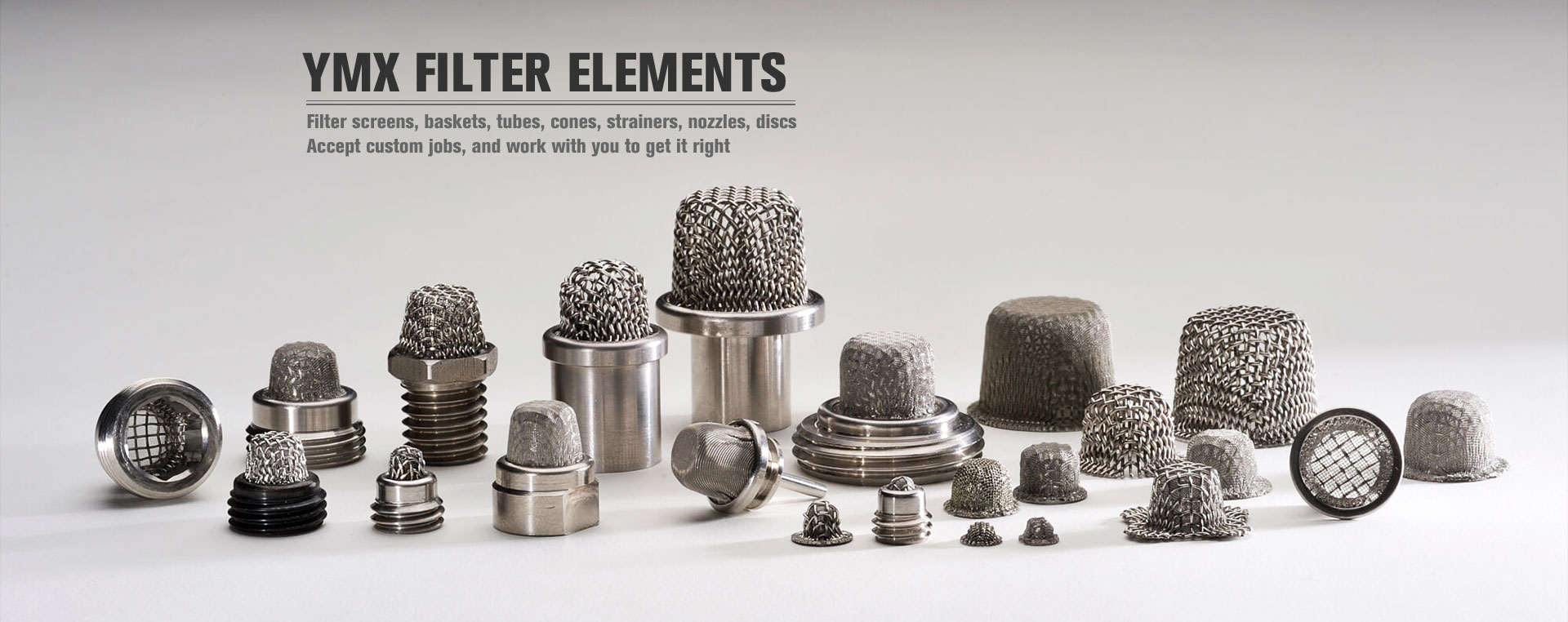

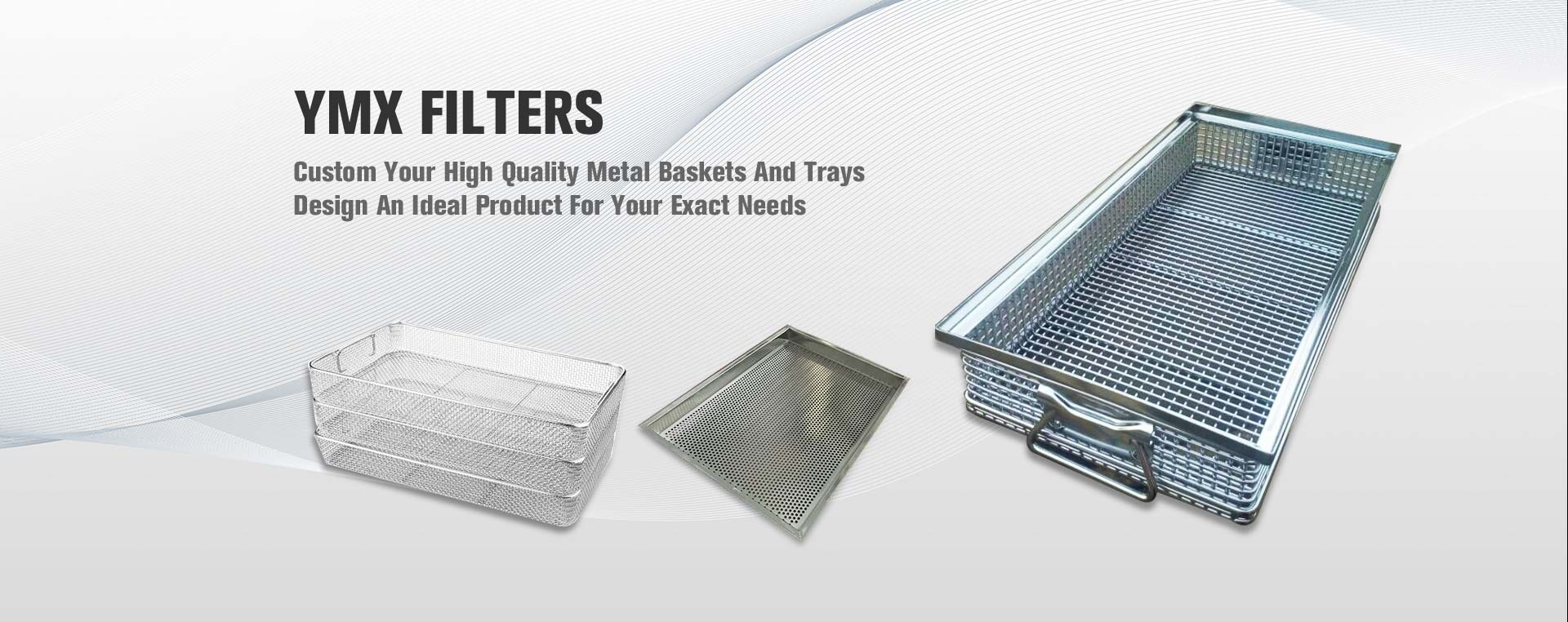

We make large range of wire mesh filter and strainer products. We can accept OEM orders, and also custom a filter product for a specific demand.

Our main products include:

2. Woven wire cloth

3. Photo etched screen

5. Mesh strainers and filters

6. Screen tubes and cartridges

7. Mesh filter elements

These products mainly used in the following industries:

1. Water treatment

2. Oil and Gas

3. Coal and mining

4. Well driling

5. Waste water treatment

6. Food and beverage

7. Pharmaceutical

8. Pump and paper

9. Industry treatment

OUR MANUFACTURING CAPABILITIES:

We are constantly expanding and automating our manufacturing capabilities, adopting new machines and new techniques to meet customers various demands on the metal screen designs. At same time, during years of experience, we have been constantly seeking for better and more efficiently manufacturing methods, which have improved our production ability and lowered the costs.

Now our in house manufacturing facilities allow us to make the following process on the screens:

1. Material cutting and shearing

2. Wire cloth weaving

3. Photo chemical etching

4. Wedge wire welding

5. Metal plate and mesh stamping/pressing

6. Rolling of the metal sheets or mesh screens

7. Leveling of the materials

8. Welding of the metals

9. Punching holes on metal sheets (Perforating)

10. Making extra-ordinary small holes on metal sheets by the Photo etching process

11. Plastic injections on the filter screens

We can do these surface treatments on our products:

1. Manual polishing

2. Electro-polishing

3. Zinc,crome,copper plating

4. Painting (Oil painting and FC painting)

EXPERTIZED ON FILTERATION PRODUCTS

We specialize in high quality filter products. Our sales, engineering and production teams have the experience to manufacture your screen product to the highest degree of excellence. Your specifications and requirements are reviewed prior to acceptance. All of our production machines and equipment are designed and built to produce products professionally and perfect.

QUALITY CONTROL

Our ongoing efforts to strengthen YMX FILTER Quality Management System have enabled us to deliver high valued products, services and industry knowledge, satisfying our customers and winning them back when they have retention needs.

Consistently open to customer inquiries, concerns and feedback in order to best comprehend customer expectations

Quick and efficient communications between our sales, technique, and production people, to make our whole team completely understand the product, avoid any mistake on all details of the product.

We Train our employees via the best possible methods and arrangements in order to yield the finest performance from their every day occupational duties

In our manufacturing plant, a number of policies and procedures have been implemented in order to ensure that the quality of our products is at the paramount of the product applications. Each and every product manufactured is inspected by our professionals in Quality Control at various steps within its production cycle.

Our inspection procedures and reports are constantly updated and improved to align with market expectations. All machinery and tools are inspected and repaired or replaced if necessary on a regular basis in order to ensure the best product results are yielded from the manufacturing process.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used