Compact Design:

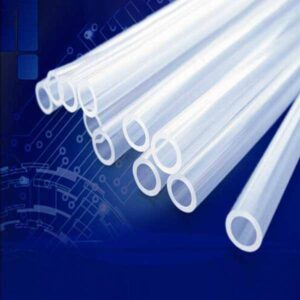

The flexible tubing used in peristaltic pumps is typically thin and compact, allowing for a smaller overall pump size compared to other pump types that require bulkier components.

This compact design makes peristaltic pumps well-suited for applications where space is limited, such as in medical devices, analytical instruments, or process equipment with tight spatial constraints.

Ease of Installation and Maintenance:

The compact tubing is easy to install, replace, and maintain, peristaltic tube as it does not require complex plumbing or additional components.

This simplicity and accessibility can reduce downtime and facilitate quick turnaround for service or tube replacement, leading to improved operational efficiency.

Versatility and Customization:

The compact tubing allows peristaltic pumps to be easily integrated into a wide range of equipment and processes, as the small footprint of the pump can be accommodated in various system designs.

The tubing can also be customized to meet specific application requirements, such as using different materials or sizes to handle different fluids or flow rates.

Fluid Isolation:

The flexible tubing acts as a physical barrier, isolating the fluid from the pump's internal components, which can be beneficial in applications where contamination or cross-contamination must be avoided.

This fluid isolation feature is particularly important in industries such as pharmaceuticals, biotechnology, and food processing, where maintaining the integrity of the fluid is critical.

Reduced Risk of Leakage:

The compact nature of the tubing, combined with the gentle pumping action, minimizes the risk of fluid leakage compared to pump types that rely on mechanical seals or gaskets.

This can contribute to improved safety, reduced environmental impact, and lower maintenance requirements.

Portability and Mobility:

The compact design of peristaltic pumps, including the tubing, allows for increased portability and mobility, making them suitable for applications that require the pump to be moved or transported, such as in mobile laboratories or field deployments.

Overall, the compact nature of the peristaltic tubing provides significant advantages in terms of space-saving design, ease of use, versatility, and reduced risk of fluid-related issues, making peristaltic pumps a preferred choice in many industrial, medical, and research applications.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used