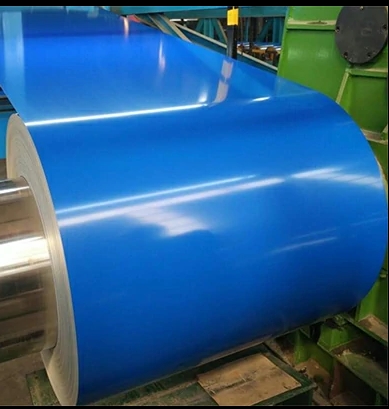

Galvanization:

The base material for PPGI coil is usually galvanized steel, where a layer of zinc is related to the steel surface to offer rust security.

The galvanization process can involve hot-dip galvanizing or electro-galvanizing, depending on the particular needs and manufacturing techniques.

Repaint Coatings:

One of the most usual surface therapy for PPGI coil is the application of a paint or finishing system.

These paint coatings can be used in a variety of shades, surfaces, and densities to meet different visual and practical requirements.

Usual paint systems used for PPGI coil include:

Polyester paint

Silicon-modified polyester (SMP) paint

Fluoropolymer-based paint (e.g., PVDF).

Acrylic-based paint.

Organic Coatings:.

Along with paint layers, PPGI coil can additionally be treated with various other natural coverings, such as:.

Plastisol finishings: A dispersion of PVC resin in a plasticizer, ppgi steel coil manufacturers giving a versatile and sturdy surface.

Polyvinyl Chloride (PVC) layers: Offer a safety and attractive layer on the PPGI surface.

Polyurethane layers: Provide improved durability, abrasion resistance, and weathering homes.

Metallic Coatings:.

Some PPGI coil might be treated with metallic finishes, such as:.

Light weight aluminum coatings: Offer a distinct metallic look and boosted rust resistance.

Copper or bronze layers: Provide an unique decorative impact and boosted weathering efficiency.

Multilayer Coatings:.

In some cases, PPGI coil may have a mix of various surface area therapies and coverings applied in numerous layers.

This can consist of a base layer of galvanization, adhered to by several layers of paint, organic coatings, or metallic layers to achieve particular efficiency and visual demands.

The option of the proper surface therapy or layer for PPGI coil depends upon elements such as the intended use, environmental problems, preferred appearance, and performance needs. Manufacturers and suppliers commonly supply a series of PPGI coil alternatives with different covering systems to fulfill the diverse needs of various applications.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used