At LECN, we have a range of state of the art 3-axis, 4-axis and 5-axis milling machines. As a designer, having an understanding of which type of machine your part will be manufactured on is critical in optimising your design. When designing a CNC machined part, you might not have thought about which type of machine your part will be machined on, but the complexity and type of geometry you can design will be different for different types of machines.

The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

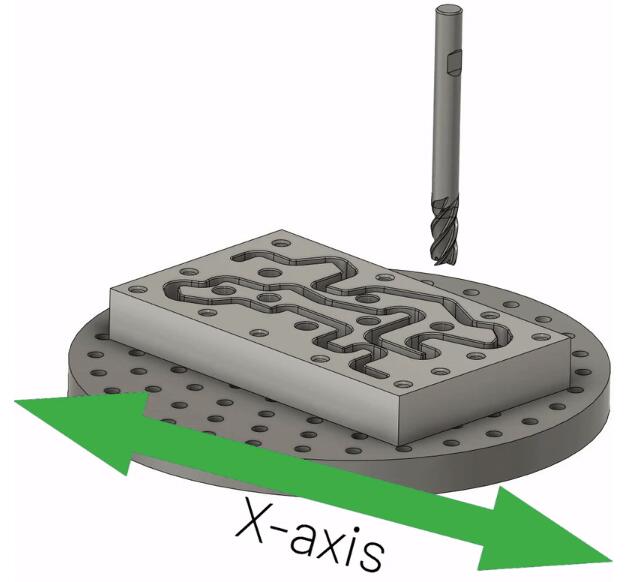

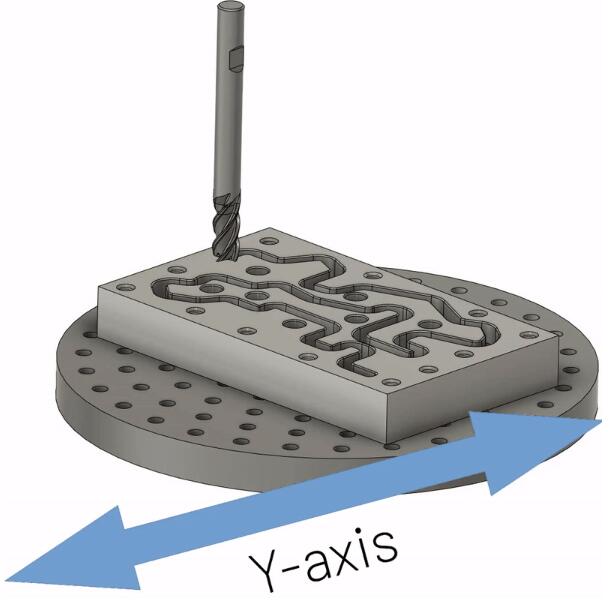

The most simple type of machining, where the workpiece is fixed in a single position. Movement of the spindle is available in the X, Y and Z linear directions.

3-axis machining

3-axis machines are typically used for machining of 2D and 2.5D geometry. Machining of all 6 sides of a part is possible in 3 axis machining but a new fixturing set-up is required for each side, which could be expensive (more on that below). For a single fixture setup, only one side of the part can be machined.

Many complex and practical shapes can be manufactured by 3 axis CNC milling, especially when in the hands of a world class CNC machining facility. 3-axis machining is best suited to manufacture of planar milled profiles, drillings & threaded holes in-line with an axis. Undercut features are possible with the use of T-slot cutters and Dovetail milling cutters.

However, sometimes the designed feature physically cannot be manufactured by a 3-axis machine, or the feature might be more economically viable to machine with a 4 or 5 axis machine.

Features not possible in 3 axis milling include any features on an angle to the X-Y-Z co-ordinate system, even if the feature itself is planar. There are two types of angled features you can design, and understanding the distinction between them is important when designing parts for CNC milling.

This is a feature machined on an angle to one of the X, Y or Z axes. For example, the planar milled surface below is at 45° to the X-axis e.g. a rotation of the A-axis.

This is a feature machined on an angle to two axes. For example the planar milled surface below is machined at a 45° angle to the X-axis, and a 30° angle to the Z axis.

Both angled and compound angle features cannot be machined by 3-axis CNC machines.

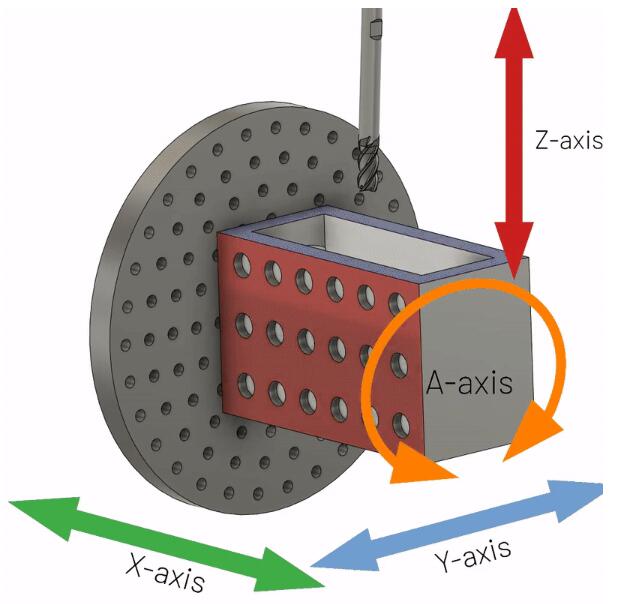

This adds a rotation about the X-axis, called the A-axis. The spindle has 3 linear axes of movement (X-Y-Z), like in 3-axis machining, plus the A-axis occurs by rotation of the workpiece. There are a few different arrangements for 4 axis machines, but typically they are of the ‘vertical machining’ type, where the spindle rotates about the Z axis. The workpiece is mounted in the X-axis and can rotate with the fixture in the A-axis. For a single fixture setup, 4 sides of the part can be machined.

4-axis machining can be used as a more economically viable way of machining parts theoretically possible on a 3-axis machine. As an example, for a part we recently machined we found that using a 3-axis machine would have required two unique fixtures at a cost of £1000 and £800 respectively. By utilising the A-axis capability of 4-axis machining, only one fixture was required at a cost of £1000. This also eliminated the need for fixture change-overs, reducing costs even further. Eliminating the risk of human error meant we machined the part to a high quality with no need for expensive Quality Assurance investigations. Removing the need to change fixtures has the additional benefit that tighter tolerances can be held between features on different sides of the part. Loss of accuracy due to fixturing and re-setup has been removed.

There are two types of 4-axis CNC machining: indexing and continuous.

Index 4-axis CNC machining is when the 4th axis (A-axis) rotates whilst the machine is not cutting material. Once the correct rotation is selected, a brake is applied and the machine resumes cutting.

In continuous 4-axis machining, the machine can cut material at the same time as the A-axis rotation, simultaneously. This allows complex arcs to be machined, such as the profile of cam lobes, and helixes.

4-axis machining gives us the ability to machine angled features, otherwise not possible with a 3-axis machine. Bear in mind that 4-axis machining allows a single axis of rotation per fixture setup, so all angled features must be angled about the same axes, or additional fixtures put in place.

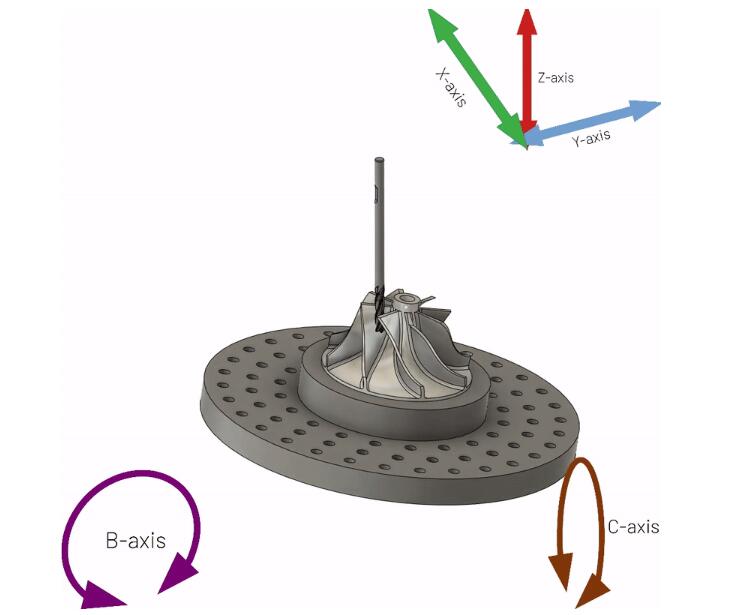

These CNC milling machines utilise 2 of the 3 possible rotation axis, depending on the type of machine. A machine will either utilise a rotation in the A-axis and C-axis, or a rotation in the B-axis and C-axis. The rotation either occurs by the workpiece, or by the spindle.

There are two main types of 5-axis CNC machines, 3+2 machines, and fully continuous 5-axis machines.

In 3+2 axis machining two rotational axes operate independently to each other, meaning that the workpiece can be rotated to any compound angle in relation to the cutting tool for features to be machined. However, two axes rotation at the same time as machining is not possible. 3+2 machining can produce highly complex 3D shapes. Fully continuous 5-axis machining can simultaneously rotate the two rotation axis, at the same time as machining and the cutting tool moving linearly in XYZ co-ordinates.

5-axis machining

Continuous 5-axis machining can produce highly complex 3D shapes, not only planar compound angled features but complex curved 3D surfaces, giving us the ability to produce parts normally reserved for moulding processes.

5-axis machining gives designers a huge level of flexibility to design very complex 3D geometry. Understanding the possibilities of each type of CNC machining is essential in design of CNC machined parts. If your design needs the use of a 5-axis CNC, make the most of it! Which other features could benefit from the capabilities of 5-axis machining?

Get in touch with us to see what is possible!

Previous: What are the typical size ranges available for grooved joint pipe fittings?

Next: What advancements have been made in the fire-resistant properties of insulation ceramic fiber?

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used