This machinery plays a crucial role in fabricating wire netting used in various applications such as fencing, animal enclosures, agricultural uses, and civil engineering projects like gabions. By automating the process of weaving wires into a hexagonal mesh, the machine enhances productivity and ensures uniformity in the mesh size and quality.

Key Parameters of Hexagonal Wire Netting Machine

Several key parameters define the performance and capabilities of a Hexagonal Wire Netting Machine:

Mesh Size: This parameter determines the size of the hexagonal openings in the netting.

Wire Diameter: This specifies the thickness of the wire used, impacting the durability and application of the mesh.

Material Capability: This indicates the type of wire the machine can process, including galvanized steel, stainless steel, or PVC-coated wire.

Speed of Production: This measures the amount of mesh produced per minute, affecting overall output.

Power Consumption: This details the energy requirements for operation, an important factor for calculating operational costs.

Machine Size and Weight: This is essential for determining the space needed for installation and the logistics of machine handling.

Common Sizes of Hexagonal Wire Netting Machines

Hexagonal Wire Netting Machines come in various sizes to accommodate different production needs and scales of operation. Here are some common specifications:

Small-Scale Machines

Mesh Size: 1/2 inch (1.27 cm)

Wire Diameter: Up to 0.7 mm

Typical Output: 30 square meters per hour

Ideal for: Small farms, domestic uses, and minor fencing needs

Medium-Scale Machines

Mesh Size: 3/4 inch to 1 inch (1.9 cm to 2.54 cm)

Wire Diameter: 0.7 mm to 1.0 mm

Typical Output: 60 to 100 square meters per hour

Ideal for: Poultry fencing, garden fencing, and medium-sized agricultural applications

Large-Scale Machines

Mesh Size: 1.5 inches to 2 inches (3.81 cm to 5.08 cm)

Wire Diameter: 1.0 mm to 2.0 mm

Typical Output: 150 to 200 square meters per hour

Ideal for: Industrial applications, large agricultural projects, and gabion production

Customization Capabilities of Hexagonal Wire Netting Machines

To meet diverse market demands, Hexagonal Wire Netting Machines offer various customization options:

Adjustable Mesh Size: This allows the machine to produce different sizes of hexagonal mesh with simple adjustments.

Variable Wire Feed: This supports different wire diameters for versatility in application.

Material Handling: This includes options to handle different types of wire coatings, such as galvanized and PVC-coated.

Automated Control Systems: These enhance precision and ease of operation with programmable settings and digital interfaces.

Hexagonal Wire Netting Machine Models

We can supply hexagonal wire netting machines for producing different hexagonal mesh products.

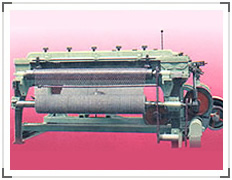

Hex01 Heavy Type Hexagonal Wire Netting Machine

The Hex01 Heavy Type Hexagonal Wire Netting Machine is specially designed to produce large-size and heavy-duty hexagonal wire meshes, both PVC-coated and galvanized, for fence and stone gabion applications. It has nine models for three sizes of meshes, and the maximum netting width is up to four meters. This series of machines is known for high efficiency in production and ease of operation and maintenance. We can also supply the complete set of equipment for your entire netting workshop.

Hex02 Hexagonal Wire Netting Machine

The Hex02 Machine is designed to produce hexagonal meshes with galvanized low carbon steel wires. It is suitable for structural, heat insulation, protective, and fencing applications. The machines in this series have a horizontal design, ensuring smooth running and high productivity.

Additional Equipment

We also supply special coiling machines and bobbin winding machines as spare parts, ensuring comprehensive support for your wire netting production needs.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used