Mechanical joint tees help manage pressure surges in piping systems through their design and installation.

Reinforced Construction: Mechanical joint tees are typically constructed with robust materials such as ductile iron or stainless steel, designed to withstand high-pressure conditions and resist deformation or failure during pressure surges.

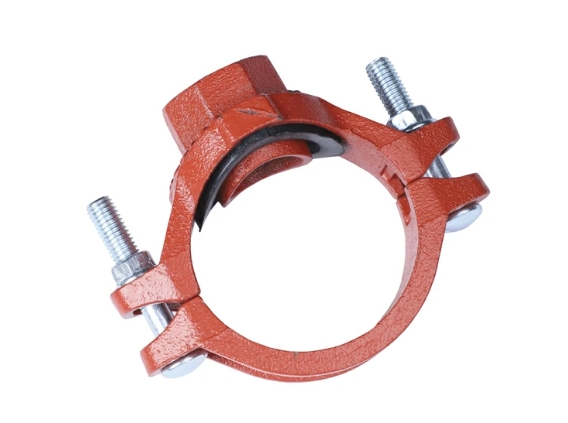

Secure Connection: Mechanical joint tees feature a secure connection method, such as a grooved, bolted, or welded joint, which ensures that the tee is firmly attached to the piping system. This secure connection helps prevent leaks or separation of components during pressure surges.

Damping Effect: The mass and stiffness of mechanical joint tees can help absorb and dissipate energy from pressure surges, reducing the intensity of the surge before it reaches downstream components. This damping effect helps protect sensitive equipment and components from damage caused by sudden changes in pressure.

Expansion and Contraction: Mechanical joint tees accommodate thermal expansion and contraction of the piping system, which can help alleviate pressure surges caused by temperature fluctuations. By allowing the piping system to expand and contract freely, mechanical joint tees help minimize stress and pressure build-up within the system.

Alignment and Support: Proper alignment and support of mechanical joint tees within the piping system are crucial for managing pressure surges effectively. Misaligned or improperly supported tees can create weak points in the system where pressure surges are more likely to occur.

Pressure Relief Devices: In some cases, pressure relief devices such as pressure relief valves or surge suppressors may be installed downstream of mechanical joint tees to further mitigate the effects of pressure surges. These devices help regulate pressure within the system and prevent damage to downstream components.

System Design: The design of the piping system, including the layout, sizing, and configuration of components, can influence how pressure surges are managed. Properly designed systems with adequate capacity and redundancy are better equipped to handle pressure surges without causing damage or disruption.

By incorporating these features and considerations into the design and installation of mechanical joint tees, piping systems can effectively manage pressure surges and maintain reliable operation under various operating conditions. Regular inspection and maintenance of mechanical joint tees are also essential for ensuring their continued performance and integrity in the face of pressure surges and other dynamic forces.

Previous: WPC Extrusion Mould For WPC Door Board

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used