Operating a food extruder machine comes with inherent risks, but with the right safety measures in place, these risks can be mitigated effectively. Whether you're a seasoned operator or new to the process, understanding and implementing safety protocols is crucial for a smooth and secure manufacturing operation.

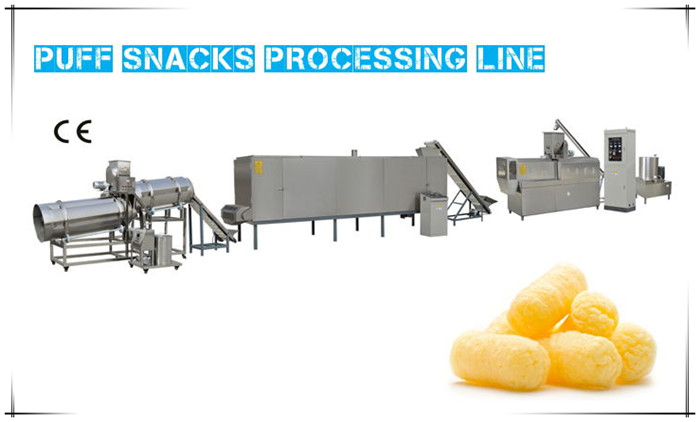

Food extruder machines are versatile pieces of equipment used in the food industry to process various ingredients into finished products. These machines apply heat, pressure, and mechanical force to transform raw materials into desired shapes and textures, such as snacks, cereals, and pet foods.

Ensuring the safety of personnel and equipment is paramount when operating food extruder machines. Here's a detailed look at seven essential safety measures every operator should follow:

Operating a food extruder machine requires adherence to strict safety protocols to prevent accidents and injuries. Here are the key safety measures to consider:

Before operating a food extruder machine, all personnel should receive comprehensive training on equipment operation, safety procedures, and emergency protocols. Supervision by experienced staff is essential, especially for new operators.

Wearing appropriate PPE, such as safety goggles, gloves, and steel-toed boots, is crucial to protect against hazards like high temperatures, flying debris, and chemical exposure. PPE should be worn at all times during machine operation.

Regular inspection and maintenance of food extruder machines are essential to identify potential hazards and prevent equipment malfunction. Any damaged or worn parts should be replaced promptly to ensure optimal performance and safety.

Monitoring and controlling the temperature of the extrusion process is critical for product quality and safety. Operators should regularly check temperature gauges and thermocouples to prevent overheating and minimize the risk of fires or burns.

Every food extruder machine should be equipped with an emergency stop button or switch that immediately halts operations in case of a malfunction, safety breach, or other emergencies. All operators should know the location of the emergency stop mechanism and how to use it.

Lockout/tagout procedures are essential for servicing or maintenance tasks on food extruder machines. Before performing any maintenance or repairs, operators must de-energize the equipment, isolate energy sources, and lock or tag out machinery to prevent accidental start-ups.

Maintaining a clean and organized work environment is crucial for safe food extrusion operations. Regular housekeeping practices, such as removing debris, spills, and waste materials, help prevent slips, trips, and falls, reducing the risk of accidents.

Prioritizing safety measures when operating food extruder machine is essential to protect both personnel and equipment. By implementing proper training, PPE usage, maintenance protocols, and emergency procedures, manufacturers can create a safer work environment while maximizing productivity.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used