What should be paid attention to during the use of the tilt sensor

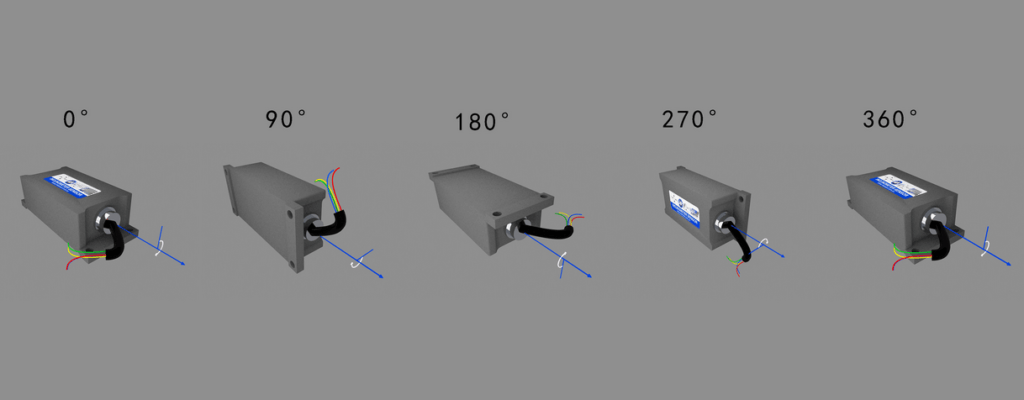

The bending radius of the cable cannot be smaller than 15mm.

The tilt sensor should not work in an environment below -40 degrees Celsius for a long time.

The tilt sensor connector cannot be disassembled by itself. Contact the manufacturer for advice.

Keep the instrument box dry and avoid long-term exposure to sunlight or rain.

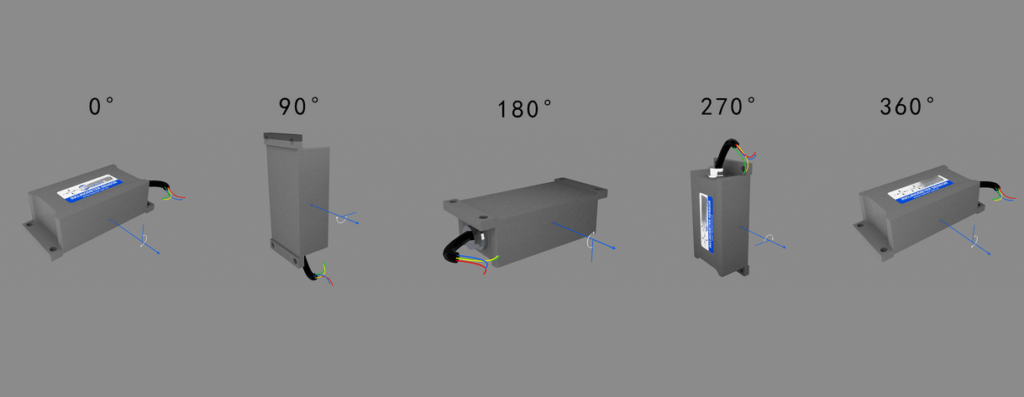

During use, the battery should avoid excessive discharge and overcharging, so as not to reduce the battery life, and the standard charging time is 10 hours.

It should be handled gently during use to prevent violent impact.

The storage and transportation process should avoid strong acids and alkalis to prevent corrosion and damage to the instrument.

Please read the data stored by the instrument in time to prevent excessive measurement data and overwrite the previous measurement data.

The cable should avoid sharp, sharp items in use to prevent cable damage.

The sensor is recommended to be returned to the factory for calibration every 3 years.

If the tilt sensor fails in the following faults, you can refer to the following solutions

1. After the product is obtained, if there is no normal output, what inspection and inspection can be done by yourself?

① First immediately turn off the power supply, check whether the working voltage meets the requirements of the manual, and check whether the wiring is correct;

② If there is no problem with the wiring, test the working current of the product, compared with the indicators on the manual, the difference is large, indicating that the product has been damaged;

③ Replace the product to confirm whether the communication line is smooth;

④ Consider whether the communication parameters are correct, such as baud rate, address, output mode, etc.

2. Inclination can not read the command normally, what can you do by yourself?

If the product is used for the first time:

① Ensure that the receiving line of the product is well connected

② Replace the product and confirm whether the communication line is smooth

③ If the product has no angular output at the same time, consider whether the communication parameters are correct, such as baud rate, address, output mode, the above points can not solve the problem, consider the host computer or communication tooling problems; If the product is used after a while, If there is a problem, and the problem disappears by replacing other products, please contact us if there is a problem with the product.

Why does the tilt switch give a false alarm? How to deal with these false alarm tilt switches?

The turbulence of the vehicle or the interference of the surrounding environment will cause the angle information of the tilt switch to change, which will lead to false alarm. Please confirm whether the above two conditions exist and test the product in the absence of the above possible conditions, if they still exist, Please contact us for questions.

The troubleshooting steps are as follows:

During the measurement process, if the displacement does not change and the counting button does not respond, please check whether the sensor connector is connected properly.

Can not be turned on, please plug in the charger, confirm the battery power is sufficient, if still can not be ruled out, please return to the factory repair.

If the battery life is obviously shortened, check whether the battery power is sufficient. If the battery power is sufficient, it indicates that the battery is aging.

If data cannot be read when connecting to the upper computer, disconnect the PC, check whether the driver is correctly installed, restart the upper computer, and try to reconnect it, and check whether the USB connector is loose.

Inaccurate measurement occurs in the use of the sensor. Please confirm whether the guide wheel and spring are loose and need to be replaced.

If the time cannot be saved during the configuration, ensure that the entered time complies with natural laws.

The hole information displayed in the configuration cannot be modified. Confirm that the hole is new and no measurement data has been saved.

In summary:

This ER-TS-4150VO sensor belongs to a single-axis wired tilt sensor. Because there are cables, the bending radius of the cable should not be less than 15mm during use. Sharp and sharp objects should be avoided during use to prevent cable damage. Its operating temperature range is -40~+85° C, but it is not suitable to work for a long time in an environment below -40 ° C. If you are using the product for the first time, be sure to ensure that the receiving line of the product is well connected, if there is no problem with the wiring, test the working current of the product, compared with the indicators on the manual, the difference is large, indicating that the product has been damaged.

The ER-TS-32600-Modbus is a wireless transmission tilt sensor, it is powered by a lithium battery, so the battery should avoid excessive discharge during use, avoid overcharging, so as not to reduce the battery life, the standard charging time is 10 hours. Please read the data stored by the instrument in time to prevent excessive measurement data and overwrite the previous measurement data.

Previous: Application of Tilt Sensor in Vehicle Four-wheel Positioning

Next: Can PE cable threading pipes truly stand the test of the elements?

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used