In today's construction industry, tile adhesives are widely used due to their excellent adhesion and anti-slip properties. However, how to further improve the anti-slip performance of ceramic tile adhesives to adapt to more complex and harsh construction environments has been the focus of many researchers. This article will explore the application of hydroxypropyl methylcellulose (HPMC) in improving the anti-slip properties of ceramic tile adhesives.

Hydroxypropyl methylcellulose (HPMC) is a common cellulose ether with excellent thickening, water retention, rheology control and reinforcing properties. Among ceramic tile adhesives, HPMC can significantly improve its anti-slip properties. Its mechanism of action mainly lies in two aspects: first, by increasing the viscosity of the tile adhesive, increasing the friction between the tile and the colloid; second, by affecting the rheological properties of the colloid, improving the anti-slip performance of the colloid.

First, the addition of HPMC will significantly increase the viscosity of tile adhesive. Viscosity is an important indicator of the internal friction of a fluid. High-viscosity colloids can provide greater friction, making the tiles less likely to slide. At the same time, HPMC can also improve the water retention of tile adhesive, reduce water evaporation, and maintain the long-term adhesion of the colloid.

Secondly, HPMC will affect the rheological properties of ceramic tile adhesive. Rheological properties refer to the deformation and flow properties of materials under stress. In ceramic tile adhesives, the addition of HPMC can change the fluidity of the colloid, making it less likely to flow and slide when exposed to external forces.

In order to give full play to the role of HPMC in improving the anti-slip performance of ceramic tile adhesives, its dosage in the colloid needs to be reasonably selected. Using too much may cause the colloid to be too viscous, affecting construction operations; using too little may not achieve the expected anti-slip effect. At the same time, it is also necessary to pay attention to the ratio of HPMC to other raw materials to give full play to the advantages of each component.

In addition, the construction environment and usage methods will also have an impact on the anti-slip performance of tile adhesive. For example, when constructing in a humid environment, the formula of the tile adhesive needs to be appropriately adjusted to adapt to the ambient humidity; when transporting or stacking tiles, severe vibrations and impacts should be avoided to avoid damaging the structure of the colloid and reducing its anti-slip performance.

In summary, hydroxypropyl methylcellulose (HPMC) is an effective modifier that can improve the anti-slip performance of tile adhesive. However, in order to obtain the best performance, it is necessary to make a reasonable selection of its dosage in the tile adhesive, and pay attention to adapting to different construction environments and correct usage methods. Hopefully this information will help you better understand and apply tile adhesive to improve its anti-slip properties.

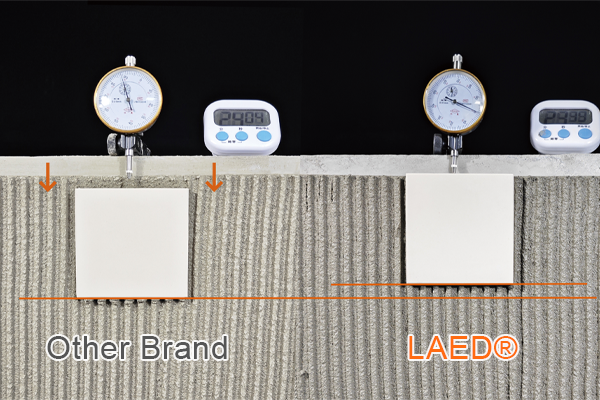

LEAD® modified HPMC produced by Hebei Yida Cellulose Co., Ltd. is a high-performance admixture specially used for tile adhesives. It can improve the opening time, slip resistance, and workability of tile adhesives. Comply with C1, C2, C1E, C2E, C1T, C2T and many other international standards.

Contact us to get free samples.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used