In the dynamic landscape of automotive engineering, precision and reliability are paramount. When it comes to evaluating and enhancing the performance of engines, the use of an engine test bench proves to be an indispensable tool. This article explores the numerous advantages of incorporating engine test benches into the performance testing process, shedding light on the pivotal role they play in optimizing engine efficiency.

One of the primary advantages of utilizing an engine test bench is the ability to conduct tests under controlled and repeatable conditions. Unlike on-road testing, where external variables can significantly impact results, a test bench provides a stable environment, allowing engineers to precisely measure and analyze the performance of an engine.

Engine test benches enable meticulous data collection, providing engineers with real-time and highly accurate performance metrics. This data includes information on factors such as horsepower, torque, fuel efficiency, and emissions, allowing for a comprehensive understanding of an engine's behavior under different operating conditions.

The use of an engine test bench accelerates the prototyping and development phases. Engineers can swiftly test various configurations, fuel formulations, and component changes without the time constraints and logistical challenges associated with on-road testing. This expedites the overall development process and facilitates quicker iterations for optimal engine performance.

By identifying performance bottlenecks and areas for improvement in a controlled setting, engine test benches contribute to cost-effective optimization. This allows engineers to refine engine designs without the need for extensive on-road testing, reducing both time and expenses associated with the development cycle.

Engine test benches allow for the simulation of diverse load conditions, mimicking real-world scenarios. This capability is crucial for evaluating an engine's performance across a spectrum of driving conditions, from highway cruising to steep inclines, providing a comprehensive understanding of its capabilities and limitations.

Stress testing on an engine test bench enables engineers to assess the durability and endurance of engine components. This includes analyzing the engine's performance under extreme conditions, ensuring that it can withstand the rigors of long-term use without compromising reliability.

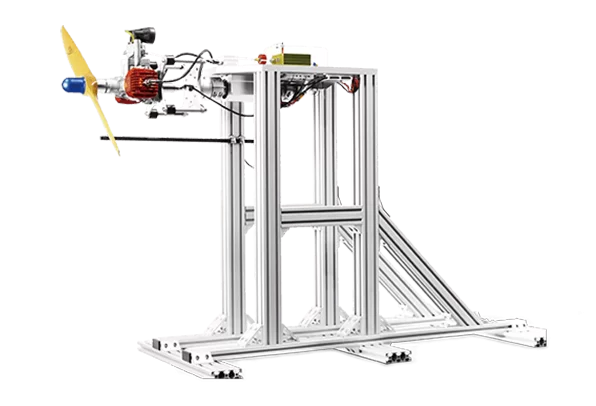

WingFlying Engine test bench facilitate application-specific tuning, allowing engineers to optimize engine performance for different vehicle types or operational requirements. Whether it's a high-performance sports car or a fuel-efficient commuter vehicle, the flexibility of a test bench enables fine-tuning to meet specific application demands.

In an era where environmental sustainability is a key concern, engine test benches play a crucial role in optimizing emission control systems. Engineers can fine-tune combustion parameters to minimize emissions while maintaining optimal engine efficiency.

In conclusion, the advantages of using an engine test bench for performance testing are multifaceted. From providing a controlled testing environment to enabling efficient development cycles and comprehensive performance analysis, these tools are indispensable in the pursuit of automotive engineering excellence. As industries continue to push the boundaries of engine innovation, the engine test bench stands as a cornerstone for achieving precision, reliability, and efficiency in performance testing protocols.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used