Reduced Manual Labor: Automation significantly reduces reliance on manual labor. Automated processes handle various tasks, minimizing the need for human intervention in repetitive or physically demanding activities.

Consistency and Precision: Automated systems ensure consistent quality and precision in brick or block production. They precisely control parameters such as mixing, compaction, and molding, leading to uniformity in size, shape, and composition.

Increased Speed and Productivity: Automation enables faster production cycles and higher throughput. Machines operate continuously and efficiently, increasing the overall speed and productivity of brick or block manufacturing.

Optimized Material Handling: Automated material handling systems precisely measure and dispense raw materials, minimizing waste and optimizing material usage. This efficiency reduces costs and enhances productivity.

Quick Changeovers and Flexibility: Some automated machines allow for rapid changeovers between different molds, sizes, or designs. This flexibility minimizes downtime and boosts operational efficiency.

Integrated Quality Control: Automation includes in-line quality control mechanisms that inspect produced bricks or blocks in real-time. Defective products can be identified and removed automatically, ensuring a higher percentage of usable output.

Data Monitoring and Analysis: Automated systems collect and analyze production data in real-time. This information helps identify bottlenecks, optimize processes, and make data-driven decisions to enhance efficiency.

Remote Monitoring and Control: Advanced automation allows for remote monitoring and control of machines. Operators can oversee operations from a distance, addressing issues promptly and minimizing downtime.

Safety and Risk Reduction: Automated systems often include safety features that minimize risks to workers. They operate in a controlled and predictable manner, reducing the likelihood of accidents.

Conservation of Energy and Resources: Automation optimizes energy consumption and resource utilization, reducing waste and environmental impact while maximizing efficiency.

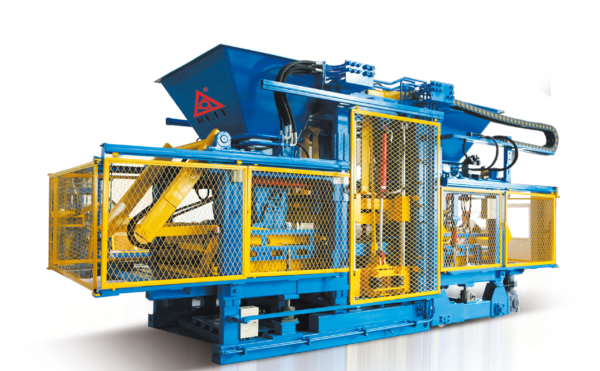

By integrating automation into brick block making machines, manufacturers can achieve higher efficiency, increased output, improved quality control, reduced operational costs, block making machinery and a safer working environment. Automation streamlines processes, making brick or block manufacturing more efficient, productive, and reliable.

Brick block making machines contribute to sustainable construction practices and environmental conservation in several ways:

Reduced Resource Consumption: These machines optimize material usage by accurately measuring and controlling the amount of raw materials required for each brick or block. This minimizes waste and reduces the consumption of natural resources.

Use of Recycled Materials: Some block making machines are designed to incorporate recycled materials, such as crushed aggregates or industrial by-products, into brick or block production. This reduces the demand for virgin materials and promotes recycling.

Energy Efficiency: Modern brick block making machines are designed to operate efficiently, consuming minimal energy while maintaining high productivity. Energy-efficient systems contribute to reduced operational costs and environmental impact.

Lower Emissions: Advanced machinery incorporates technologies that reduce emissions and pollutants released during the production process. This contributes to improved air quality and reduced environmental pollution.

Conservation of Water: Some machines optimize water usage during the manufacturing process, minimizing water consumption or incorporating recycling systems to reuse water in the production cycle.

Longer Lifespan of Bricks or Blocks: By ensuring consistent quality and durability, these machines produce bricks or blocks that have longer lifespans. Durable construction materials reduce the need for frequent replacements, leading to less waste generation over time.

Sustainable Building Practices: Bricks or blocks produced by these machines often contribute to energy-efficient and sustainable building designs. They provide better insulation, reducing energy consumption in buildings over their lifetime.

Support for Green Building Certifications: Blocks or bricks manufactured using sustainable practices from these machines may contribute to meeting criteria for green building certifications, such as LEED (Leadership in Energy and Environmental Design).

Optimized Waste Management: Through precise control over materials and processes, these machines minimize waste generation during brick or block production, supporting efficient waste management practices.

Promotion of Sustainable Development Goals: By reducing environmental impact, conserving resources, and promoting sustainable construction practices, these machines align with global sustainability goals and initiatives.

Overall, brick block making machines, when operated with sustainable practices, contribute significantly to reducing the environmental footprint of construction activities, fostering eco-friendly building practices, and promoting a more sustainable construction industry.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used