Regular Visual Inspections: Perform regular visual inspections of the butterfly valve to check for any signs of damage, wear, or leakage. Look for corrosion, erosion, cracks, or deformities in the valve body, disc, stem, and sealing components. Inspect the valve for any loose fasteners or signs of misalignment.

Lubrication: Lubricate the moving parts of the butterfly valve as per the manufacturer's recommendations. This typically involves applying a suitable lubricant to the stem, bearings, and other friction points to ensure smooth operation and reduce wear.

Leakage Checks: Periodically check the butterfly valve for any leakage by conducting a leak test. This can be done by applying a suitable test medium, such as water or air, to the valve while it is closed and monitoring for any visible leakage or pressure drop.

Actuator Inspection and Maintenance: If the butterfly valve is equipped with an actuator (e.g., electric, pneumatic, hydraulic), inspect and maintain the actuator according to the manufacturer's instructions. This may include checking the actuator's electrical connections, pneumatic/hydraulic lines, and control settings.

Seal Replacement: Over time, the sealing components of the butterfly valve, such as the seat or O-rings, may wear out or deteriorate. Inspect these seals regularly and replace them as needed to maintain proper sealing integrity.

Operational Testing: Periodically test the operation of the butterfly valve to ensure it opens and closes smoothly and without any binding or sticking. Verify that the valve operates within the specified torque or actuator force requirements.

Corrosion Protection: Implement appropriate corrosion protection measures for butterfly valves that are installed in corrosive environments. This may involve applying protective coatings or using corrosion-resistant materials during the valve construction.

Calibration: If the butterfly valve is equipped with position indicators or limit switches, calibrate them periodically to ensure accurate feedback and control signals.

Documentation and Record-Keeping: Maintain a record of all maintenance activities, inspections, repairs, and replacements performed on the butterfly valve. This documentation can help track the valve's history, identify trends, and facilitate future maintenance planning.

It's worth noting that the specific maintenance and inspection requirements can vary depending on the design, materials, and application of the butterfly valve. Refer to the manufacturer's guidelines and recommendations for the specific valve model and consult with qualified personnel or valve experts to ensure that you are following the appropriate maintenance practices for your butterfly valve.

The main difference between lug-style and wafer-style butterfly valves lies in their design and method of installation. Here's an overview of each type:

Lug-Style Butterfly Valve:

A lug-style butterfly valve has threaded inserts, known as lugs, on the valve body. These lugs are located on both sides of the valve and serve as attachment points for bolts or studs. The valve is installed between two mating flanges using bolts that pass through the lugs and connect the valve to the flanges. Each lug has a hole that allows the valve to be bolted to the flanges, providing a secure connection.

Key features of lug-style butterfly valves include:

Attachment Points: Lugs on both sides of the valve body for bolting to the mating flanges.

Bolt Patterns: The number and spacing of the lugs follow standard flange bolt patterns, such as ANSI/ASME B16.5 or API 609.

Axial Loading: double offset high performance butterfly valve in China The lugs help bear the axial forces exerted on the valve during operation, such as pressure or thrust loads.

Ease of Installation: The lug-style design allows the valve to be installed or removed from a pipeline without disconnecting the entire system.

Wafer-Style Butterfly Valve:

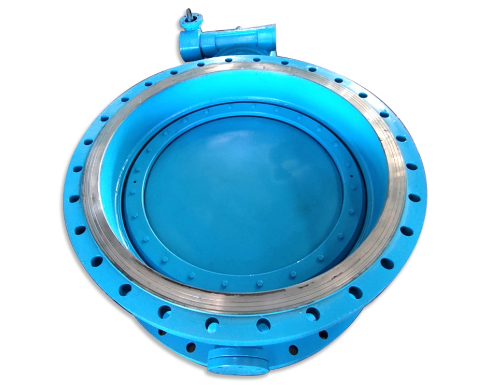

A wafer-style butterfly valve is designed to fit between two flanges without the need for additional attachment points like lugs. The valve has a slim profile with a centered circular disc that rotates within the pipeline. When the valve is fully open, the disc is parallel to the flow, minimizing pressure drop. The valve is held in place between the flanges using bolts or studs that pass through the flange holes and connect the two flanges together, clamping the valve in position.

Key features of wafer-style butterfly valves include:

Slim Design: Wafer-style valves have a compact and lightweight design, making them suitable for applications with limited space.

Installation between Flanges: The valve fits directly between the mating flanges, with the flange holes lining up for bolt connection.

Reduced Weight and Cost: The absence of lugs and additional attachment points results in a lighter valve design, which can reduce material and manufacturing costs.

Limited Axial Loading: Wafer-style valves rely on the flange bolts to bear the axial forces, such as pressure or thrust loads, exerted on the valve during operation.

It's important to note that the choice between lug-style and wafer-style butterfly valves depends on various factors such as the application, system requirements, pressure rating, and compatibility with existing piping infrastructure. It is recommended to consult with valve manufacturers or industry experts to select the appropriate valve type based on the specific needs and considerations of your application.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used