Glass Plate Level Gauge, also known as Sight Type Glass Level Gauge

Glass Plate Level Gauge is a vital instrument, extensively employed across various industries to indicate or measure the liquid level within tanks, vessels, or containers. Coming in three types – transparent, reflex, and sight glass – this versatile gauge offers clear and direct readings, significantly enhancing operational efficiency and safety.

Working Principle

The working principle of the Glass Plate Level Gauge is simple yet effective. It operates based on the fact that liquid inside a container seeks its own level. The gauge comprises a transparent glass plate secured on one or more front windows of a machined metal body, creating a sealed viewing portal. In operation, the height of the liquid within the container can be seen directly through the transparent glass plate, facilitating an accurate level reading.

Applications

Glass Plate Level Gauges are pivotal in industries where maintaining specific liquid levels is crucial for safe and efficient operations. These sectors include, but are not limited to, chemical processing, power generation, oil and gas, and food and beverage production. The gauge can withstand varying pressures and temperatures, making it suitable for a broad range of applications.

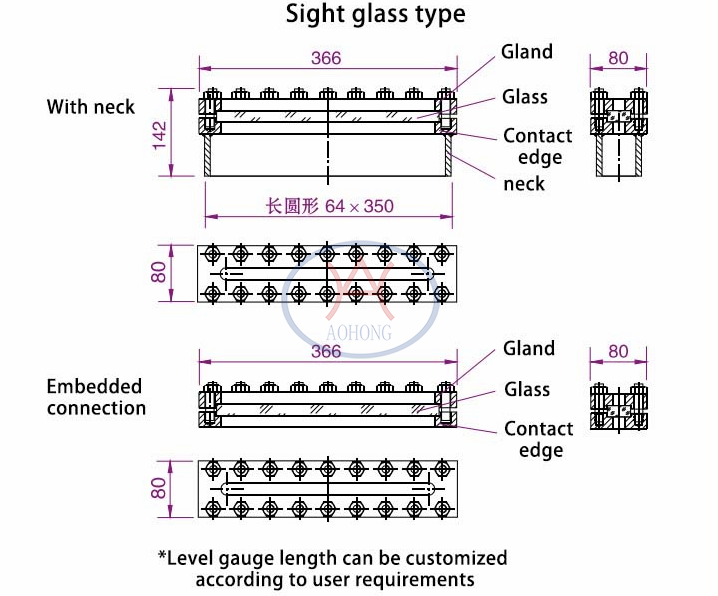

Sight glass level gauge

Glass Plate Level Gauge

Features

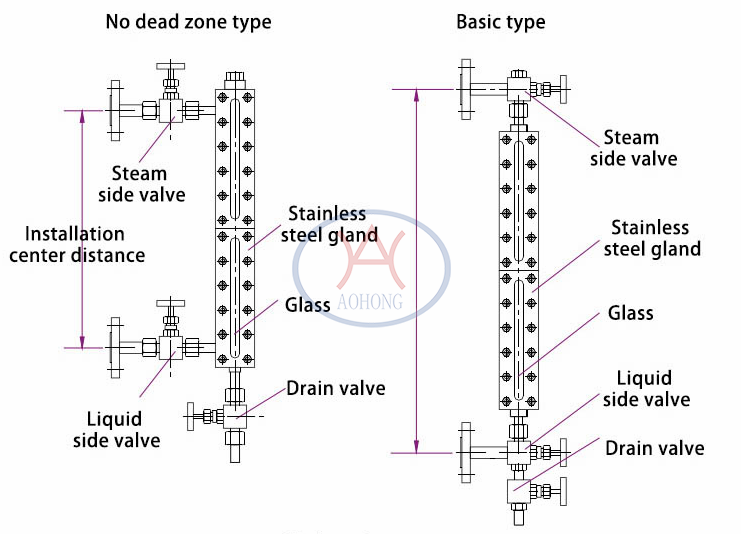

The Glass Plate Level Gauge is known for its high working temperature of up to 250°C and high working pressure of up to PN300. With a clear and direct reading mechanism, it offers excellent sealability. It stands out due to its long lifespan, simple structure, and ease of installation and maintenance. In case of glass damage, the gauge is equipped with a safety mechanism – an insurance steel ball that automatically seals the gas and liquid side valves, minimizing potential hazards.

Clear and direct reading, good sealability.

High working temperature: ≤+250°C.

High working pressure: ≤PN300.

Long lifetime, simple structure, easy installation and maintenance.

This level gauge features an ingenious safety design with an insurance steel ball. Should the glass plate crack or suffer damage, this ball immediately halts the flow from the gas and liquid side valves, reducing potential flow. This allows operators to shut off the bottom valve safely to deal with the issue, making it a reliable choice for containers operating under middle or low pressure.

| Recommended center-center distance: | 300, 500, 800, 1100, 1400,1700,2000mm(custom made) |

| Indicate mode: | single color, bicolor(red as vapor phases, green as liquid) |

| Material: | carbon steel, 304,316L, 1Cr18Ni9Ti, 0Cr18Ni9, 304 with PTFE lining |

| Nominal pressure: | PN6-PN100(×0.1MPa) |

| 304 +PTFE≤PN40 | |

| PP≤100°C | |

| Working temperature: | carbon steel ≤350°C |

| Stainless steel ≤450°C | |

| 304+PTFE ≤200°C | |

| PP≤100°C | |

| Drain valve: | drain needle valve (or customize) |

| Vent valve: | vent needle valve (or customize) |

| Process flange: | DN20/RF HG/T 20592-09 |

| The heat steam interface: | ZG1/2″male screw thread |

| The heat steam pressure: | ≤1.0Mpa |

| Eclectic heating: | self-limiting temperature heating (unnecessary for anticorrosive type) |

| Steel ball self-closing pressure: | ≥0.3Mpa |

| Power supply: | 24V DC, 36V AC |

| Environment temperature: | -50~+80°C |

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used