The reason why we chose to use aluminum profiles is because it is structurally stable and resistant to corrosion during long-term use. However, some aluminum profiles have corrosion on the surface, which is mainly due to the fact that the proportion of the material used in the manufacture of the aluminum profile is not used correctly. As a 60 Roller Track Supplier, let's analyze what causes the aluminum profile to corrode.

1. The proportion of magnesium and silicon added during the casting process is not suitable. For example, some of the surplus silicon exists. In addition to a small amount of silicon in the free state, a portion of the surplus silicon will form a ternary compound in the aluminum alloy. These insoluble impurity phases or free impurity phases formed in the alloy tend to accumulate on the grain boundaries, while weakening the strength and toughness of the grain boundaries, and become the weakest link of corrosion resistance, from which corrosion first occurs.

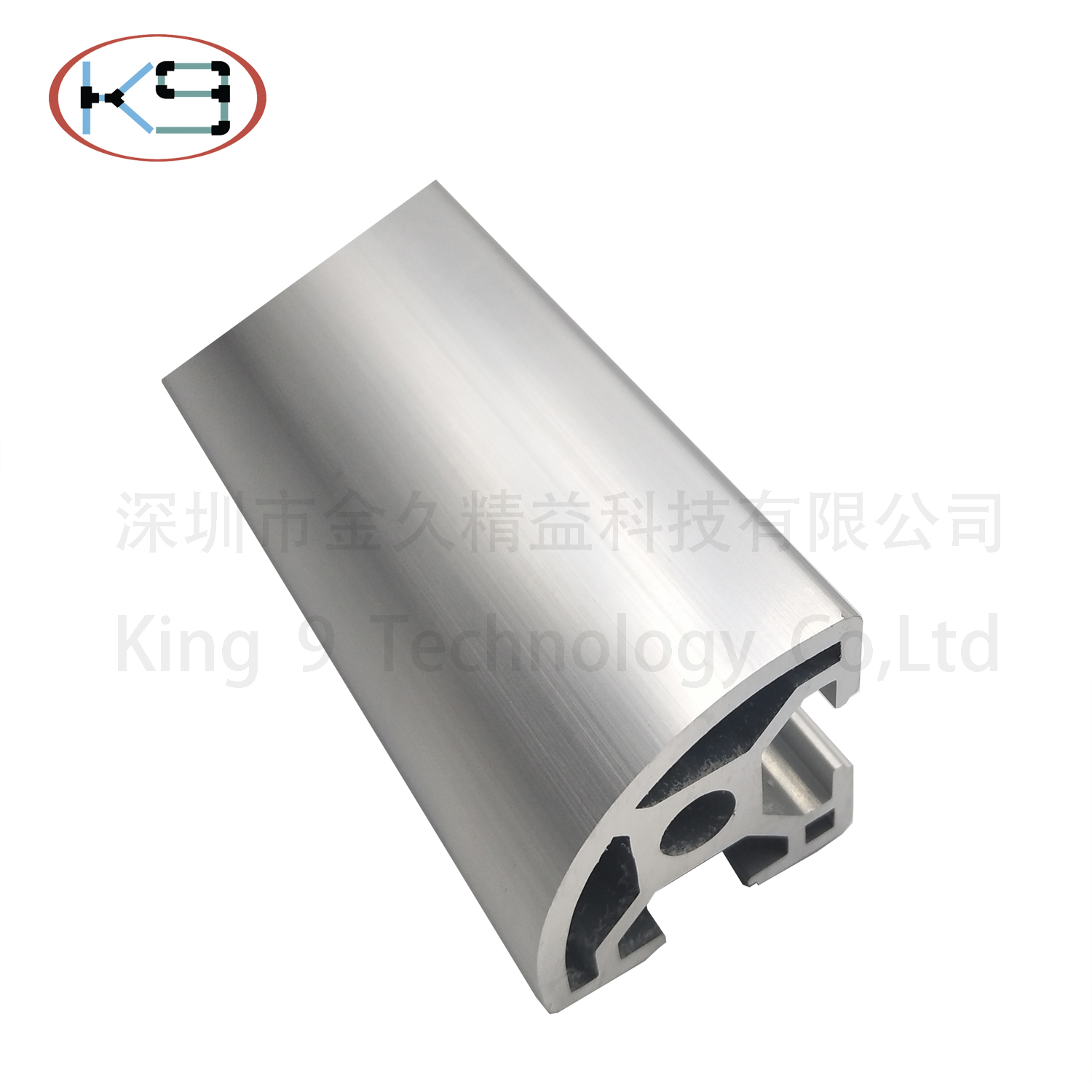

Our company provides Aluminium Profile System, if you are interested in our products, please contact us.

Previous: Anti slip Rubber Sheet

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used