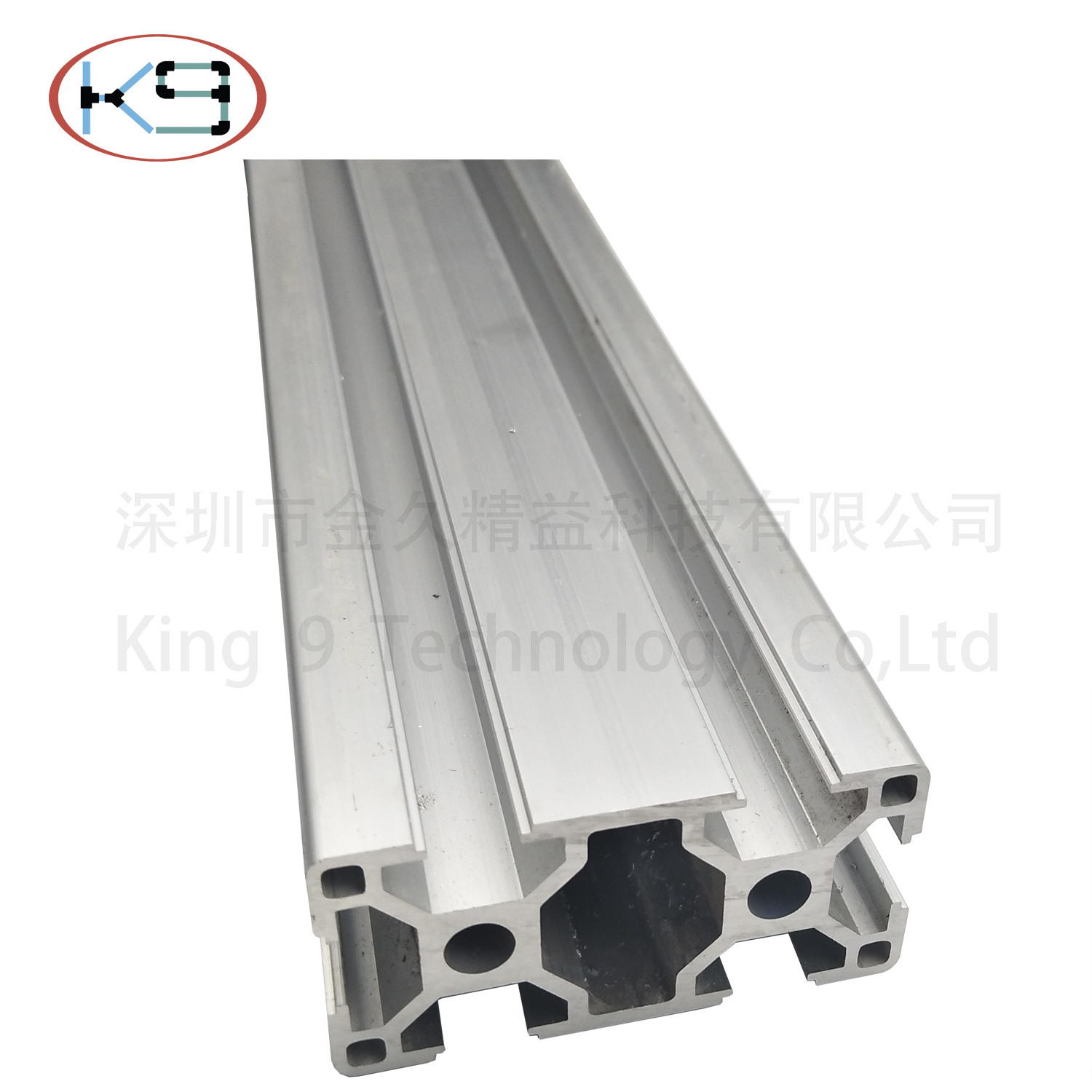

As a 60 Roller Track Supplier, let's talk about the Aluminium Profile post-oxidation treatment.

Four points to note in the Aluminium Profile oxidation post-treatment process:

(1) Hot water rinse. The purpose of hot water washing is to age the film. However, the water temperature and time should be strictly controlled. When the water temperature is too high, the film layer is thinned and the color is lightened. The above-mentioned similar problems may occur when the processing time of the industrial aluminum profile is too long. The suitable temperature and time are: the temperature is 40 to 50 ° C for 0.5 to 1 min.

(2) Drying. It is better to dry and dry naturally. The workpiece filled with hot water is slanted on the shelf, so that the free water on the working surface flows downward in the straight direction. The water droplets flowing to the lower corner are sucked with a towel, and the color of the film dried by this method is not affected and appears natural.

(3) Aging. The Aluminium Profile aging method can be determined according to the climatic conditions. In the summer with sunlight, it can be exposed to sunlight, and it can be baked in the rainy or winter season. The process conditions are: temperature 40~50 °C for 10-15 minutes.

(4) Rework of the unqualified Aluminium Profile. Unqualified conductive oxide film parts should be picked out before drying and aging process. Because of drying and aging, the film layer is difficult to remove and will affect the surface roughness of the workpiece. Firstly, the unqualified workpiece is clamped on the fixture for aluminum anodizing, and then anodized according to the anodizing method of aluminum in sulfuric acid solution for 2 to 3 minutes. After the film layer is soft and peeled off, the alkali solution is slightly cleaned and nitric acid is added. Conductive anodization can be re-executed after light is emitted.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used