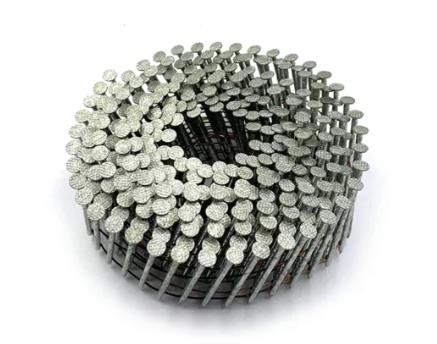

Plastic collated coil nails are a type of fastener used in construction and carpentry. They consist of a long, thin nail that is coiled and held together by a strip of plastic. The plastic strip serves as a collation system, which allows the nails to be loaded into a pneumatic nail gun for efficient and rapid installation.

Increased Productivity: Plastic collated coil nails are a time-saving alternative to hand-nailing or using individual nails. The collation system allows for fast and efficient loading of nails into a nail gun, which can increase productivity and reduce labor costs.

Versatility: Plastic collated coil nails can be used in a variety of applications, including framing, sheathing, decking, and roofing. They are suitable for use with a wide range of materials, including wood, steel, and concrete.

Improved Accuracy: Using a nail gun with plastic collated coil nails can improve the accuracy and consistency of the nail placement. This can result in a more secure and stable connection between the materials being fastened.

Reduced Jamming: The collated system in plastic collated coil nails reduces the likelihood of jamming in the nail gun, which can be a common issue with other types of nails. This can save time and reduce frustration for the user.

Increased Holding Power: Plastic collated coil nails are often designed with ring or screw shanks, which provide increased holding power compared to smooth-shank nails. This can result in a stronger and more secure connection between the materials being fastened.

Improved Safety: Using a nail gun with plastic collated coil nails can improve safety by reducing the risk of hand injuries that can result from hand-nailing.

Overall, plastic collated coil nails offer a range of benefits, plastic collated coil nails including increased productivity, versatility, improved accuracy, reduced jamming, increased holding power, and improved safety. They are a popular choice for construction and carpentry professionals who require efficient, reliable, and consistent fastening solutions.

While plastic collated coil nails have a number of advantages, there are also some potential disadvantages to consider. Here are a few:

Cost: Plastic collated coil nails can be more expensive than other types of nails. While they can increase productivity and efficiency, the initial cost of purchasing a nail gun and the nails themselves can be higher than traditional hand-nailing methods.

Weight: The collation system in plastic collated coil nails can add weight to the nail gun, which can be tiring for the user over time. This can be especially true for extended use or when working overhead.

Waste: The plastic collation strip is not biodegradable, which can be a concern for those looking for more sustainable options. However, some manufacturers offer biodegradable collation strips as an alternative.

Compatibility: Not all nail guns are compatible with plastic collated coil nails. It's important to ensure that the nail gun you are using is designed to work with this type of fastener.

Jams: While plastic collated coil nails are designed to reduce jamming, they can still jam in the nail gun. This can be frustrating and time-consuming for the user.

Availability: Plastic collated coil nails may not be as widely available as other types of nails, which can be a concern for those in remote or rural areas.

Overall, while plastic collated coil nails offer a range of benefits, there are also some potential disadvantages to consider. Cost, weight, waste, compatibility, jams, and availability are all factors to keep in mind when deciding whether to use this type of fastener.

Previous: Choosing the Right Handheld Inkjet Printer: Features and Considerations

Next: PY Spring Cone Crusher

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used