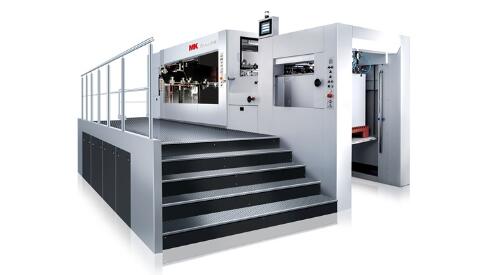

Die-cutting machines are versatile tools that have gained popularity in the crafting, scrapbooking, and manufacturing industries. They are used to cut out shapes, patterns, and designs from various materials, such as paper, cardboard, fabric, vinyl, and leather. In this article, we will introduce die-cutting machines, explain how they work, and discuss the benefits of using them for a range of applications.

What are die-cutting machines?

A die-cutting machine is a device that uses dies, or metal templates, to cut out shapes from materials. Dies can be made in a variety of shapes and sizes, depending on the intended use. They are typically made from metal, plastic, or wood, and are designed to be used with a die-cutting machine.

Die-cutting machines come in various types, from manual hand-crank machines to electronic and computerized models. Manual die-cutting machines require the user to turn a crank or handle to push the die through the material, while electronic models use a motor to drive the die. Computerized die-cutting machines are the most advanced, allowing users to create designs on a computer and then cut them out automatically using the machine.

How do die-cutting machines work?

Die-cutting machines work by pressing a die into a material, cutting out the desired shape. The die is placed on the material, and then the user cranks or feeds the material through the machine. The pressure from the machine forces the die through the material, leaving behind a cut-out shape. Depending on the machine and die used, the material can be cut, scored, or embossed.

Manual die-cutting machines require the user to turn a crank or handle to push the die through the material. Electronic models use a motor to drive the die, which is operated by pressing a button or foot pedal. Computerized die-cutting machines are connected to a computer, allowing the user to create designs using software and then cut them out automatically using the machine.

Why are die-cutting machines useful?

Die-cutting machines offer several benefits for crafting and manufacturing applications. First, they allow users to cut out shapes and patterns with precision and accuracy, saving time and effort compared to cutting by hand. This is especially useful for complex or intricate designs.

Second, die-cutting machines can cut through a range of materials, including paper, cardboard, fabric, vinyl, and leather, allowing users to create a wide variety of projects and products. For example, they can be used to make custom invitations, scrapbook pages, cards, and home decor items. In the manufacturing industry, die-cutting machines are used to cut out shapes for packaging, labels, and other products.

Third, die-cutting machines offer versatility and flexibility, as they can be used with a range of dies and accessories to create different effects. For example, embossing dies can add texture and dimension to designs, while edge dies can create intricate borders and frames.

If you want to learn more about die cutting machines, click here!

Conclusion

Die-cutting machines are versatile tools that offer precision, accuracy, and flexibility for a variety of crafting and manufacturing applications. They work by pressing a die into a material, cutting out the desired shape. With various types of machines available on the market, there is a die-cutting machine suitable for every need and budget. By using a die-cutting machine, users can save time and effort while creating unique and professional-looking projects and products.

Previous: Driving Down Expenses: How Self-Loading Mixer Trucks Lower Operational Costs

Next: 2022 Full Gold And Silver Jewelry Laser Cutting Machine Buyer Guides

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used