Annular Blowout Preventers and Ram BOPs are two critical pieces of equipment used in the oil and gas industry to prevent the uncontrolled release of well fluids during drilling and completion operations. While both serve the same purpose of well control, annular BOPs and ram BOPs have key differences in design, operation, and application.

First, there are significant differences in the design of annular BOPs and ram BOPs. Annular BOPs have a flexible annular rubber seal, also known as the "annular packing element," that expands or contracts to create a seal around the drill pipe or casing. Rubber seals are usually made of durable materials such as rubber or elastomers and are designed to provide a sealing function by compressing around the pipe or casing to prevent the flow of well fluids.

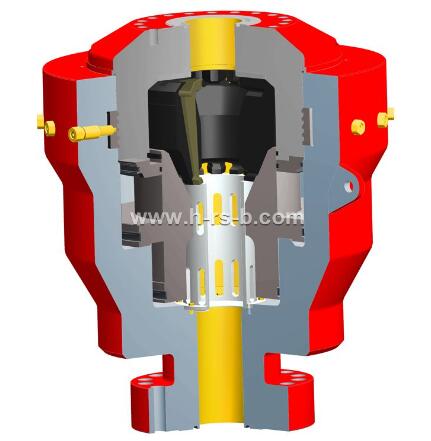

Ram BOPs, on the other hand, use a hydraulically operated steel plunger (called a "ram") to close off the drill pipe or casing and create a seal. Rams are usually made of high-strength steel and can be designed in a variety of shapes and configurations to match the size and type of drill pipe or casing being used. In emergency situations, ram blowout preventers can physically cut the drill pipe or casing to provide a stronger and more reliable seal.

Second, annular BOPs and ram BOPs operate differently in the way the seal is formed. Annular BOPs are versatile and can be used to seal pipes or casings of different sizes by expanding or contracting the rubber seal. This flexibility allows the annular BOP to be used as a secondary well control device when the primary BOP (usually a ram BOP) fails to completely seal the well. Annular BOPs are also commonly used in other operations such as pipe racking and stripping, which involves pulling or inserting drill pipe into the wellbore.

Ram blowout preventers, on the other hand, are often considered the primary well control equipment. Rams are designed to seal off drill pipe or casing and provide a mechanical and hydraulic seal capable of shearing through the pipe in an emergency. This makes the Ram BOP more robust and reliable in extreme well control situations such as blowouts or high pressure kick events.

Finally, the field application of annular BOP and ram BOP is also different. Annular BOPs are often used as secondary BOPs in conjunction with primary BOPs such as ram BOPs to provide additional sealing capability. They are usually installed above the main BOP as a backup measure in case the main BOP fails to completely seal the well. Annular BOPs are also commonly used in well completions or drilling operations where drillpipe or casing sizes may vary.

Ram BOPs, on the other hand, are often used as the primary BOP for well control. They are usually installed at the bottom of the BOP stack and are the first line of defense against uncontrolled flow of well fluids. Ram blowout preventers are designed to provide a reliable and robust seal around drillpipe or casing and are capable of shearing the pipe to prevent blowout or kick events.

In summary, while both annular BOPs and ram BOPs are used for well control in the oil and gas industry, they have key differences in design, operation, and application. Annular BOPs use flexible rubber seals and are typically used as secondary BOPs, while ram BOPs use steel rams for sealing and are considered primary well control devices. Understanding the differences between these two types of BOPs is critical to ensuring the safe and efficient operation of drilling and completion operations in the oil and gas industry.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used