A pipeline valve is mainly used in various pipeline systems for maintenance purposes. These valves play a major role in the smooth and efficient functioning of the pipelines. The valves are meant for regulating, controlling, and directing the flow of a fluid by opening, closing, or partially creating obstructions in the passage.

Furthermore, it also ensures the safety of the pipes. The valves are mainly installed in the control system. However, it is important to install only high-quality, reliable valves else it might lead to damage as well as leakage in the pipeline system.

Some of the major functions of these valves include:

Controlling the temperature by controlling the water cooling rates through a cooling line.

Controlling the flow of concentrated bases or acids through a line.

Balancing the system by restricting flow.

Avoiding reversing flow (check valves).

Automatically ceasing the flow in case of system failure.

The pipeline valves are mainly placed at specific intervals in the pipeline to control the movement and flow of the liquid. The operation of the valves is mainly dependent upon the position of the disc or rotary in it. While some valves can rotate to and fro, others can rotate either in one specific direction or a maximum in two directions.

In the case of the two-port valves, they can either remain closed to stop the flow of the fluid or open to allow its flow. In certain circumstances, the valve remains partially opened to allow the partial flow of the liquid.

In such two-port valves, the fluid can flow from one port to the other.

Some of oil pipeline valves are operated manually with the help of the handle attached to the stem of the valve. If the handle is half-turned up to 90 degrees, then it is considered the quarter turn valve. When the handle is in a completed circular position to the stem.

Even the actuators can control the functioning of the valve. The actuators are attached to the stem. They enable the valves to work in an automated manner.

The types of pipeline valves used in different piping systems are selected according to the requirements of the piping system. While some might be used only to control the flow, others might be used to regulate or throttle it.

Different types of valves in pipelines have distinct functionalities and purposes. Some of the most common pipeline valve types have been mentioned below.

Gate valves are linear motion valves that utilize a gate or disk to allow or restrict the liquid flow throughout the piping system. These valves can either be fully opened or fully closed, there is no partial movement. In case of constant flow, the gate or the wedge-shaped disk is completely open and does not obstruct the fluid flow. Moreover, there is a lesser pressure drop while the gate remains open.

For the proper sealing of the gate valve, the disk should be in contact with the surface at an angle of 360 degrees. This prevents the flow of liquid and keeps the valve completely closed. Pipeline gate valves should not be used for regulating purposes. This is because it does not control the fluid flow accurately. The higher flow intensity might often lead to disc erosion and the emission of louder noises.

The pipeline gate valves can be classified according to three different categories: type of disk, types of body bonnet joint, and the types of stem movement.

The main purposes of the globe valves are controlling, restricting, and allowing the liquid flow. T is mainly utilized in pipeline systems where leakage and flow control are necessary factors. These valves consist of the disc that moves in at a 90-degree angle to the seat to open and close the valve. The appropriate space created between the disk and the seat while closing the valve makes it appropriate for regulating the flow.

There is a lower chance of leakage in the globe valves as compared to the other valves. One of the main reasons is the perpendicular angle between the disc and the seat of the valve. The disc of the globe valve closes in the opposite direction or the same direction as the liquid flow. When the disc closes in the direction of the flow, the fluid flow is obstructed, leading to instant flow prevention.

On the other hand when the disc closes in the opposite direction of the flow, then the valve is opened allowing a smooth flow of the liquid. Although the pressure drop through the valve is not a determining factor, these valves have slightly higher pressure dips than gate/ball valves and can be employed in those situations.

These types of valves can be divided into different types based on two main factors: the type of body and the body bonnet connection.

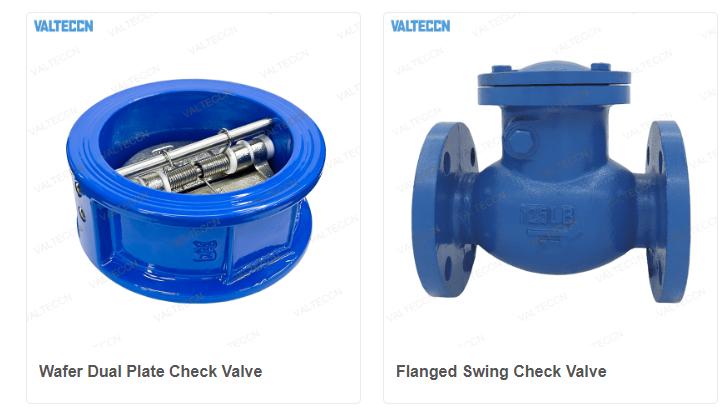

This type of valve is mainly used to control the backflow of the fluid in the piping system. They limit the flow of media in a piping system to one direction. Due to its uni-directional movement, the check valves are also known as the non-return valve. This broadly defined check valve function has different functions in various industries. It mainly opens due to the pressure exerted by the fluid flow and closes when there is a reverse flow of liquid.

The fluid can flow through these valves hassle-free. Moreover, it closes automatically as soon as the pressure decreases. The check valve mainly consists of the seat ring, cover, body, disc, and hinge pin. Moreover, these types of valves are classified based on their types of disc.

A butterfly valve, like a ball valve, operates using a half-turn mechanism. To open or close the valve, a series of centrally located flaps are used. The valve handle is connected to the stem, which is connected to the disc inside the valve. The handle’s movement causes the disc to rotate and open or close the valve. This type of valve is further classified as double eccentric, concentric, and triple eccentric.

The flow control element in a butterfly valve in pipeline is a disc that rotates on either a vertical or horizontal axis and is roughly the same diameter as the inside diameter of the adjoining pipe.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used