Scaffolding has been used for over 5,000 years as an aid to construction and maintenance and was first mentioned by the Chinese and Egyptians. As such, scaffolding has played an important role in the progress of mankind. Bamboo has long been one of the most basic elements used in scaffolding and has been called the “grass of building Asia”.

However, as time has progressed, better quality, safer and more versatile materials and designs for scaffolding have emerged. The complexity and aesthetics of design and the sheer scale of modern projects require safer and more versatile scaffolding that can support work at height while ensuring the safety of workers.

There are several different scaffolding forms in terms of their shape and structure such as trestle scaffolding, steel scaffolding, patented scaffolding, cantilever scaffolding, suspended scaffolding, single scaffolding, and double scaffolding.

These forms are based on the nature of the work and the type of raw material used to produce the scaffold.

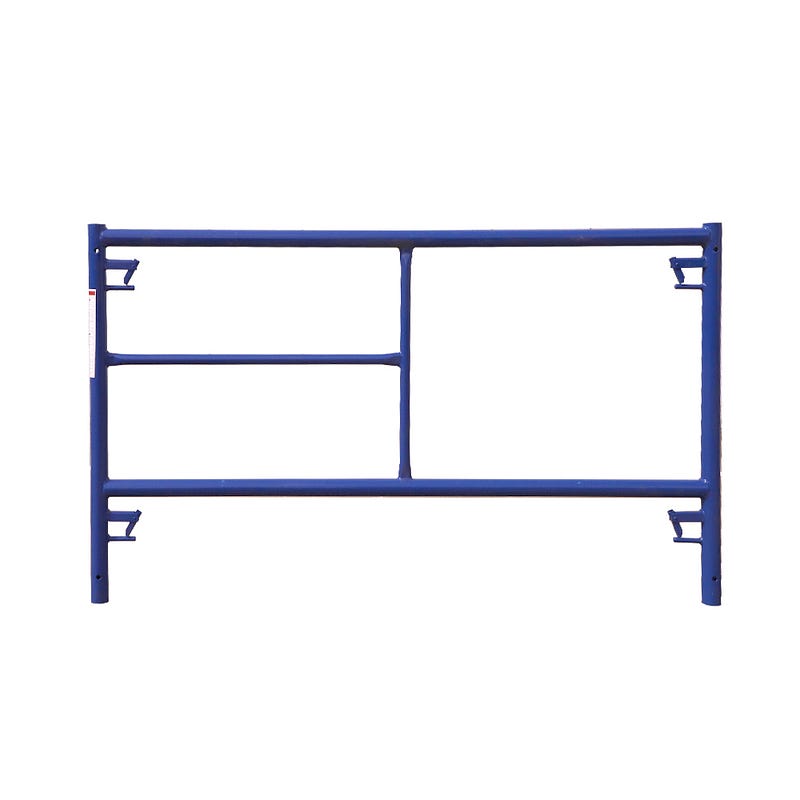

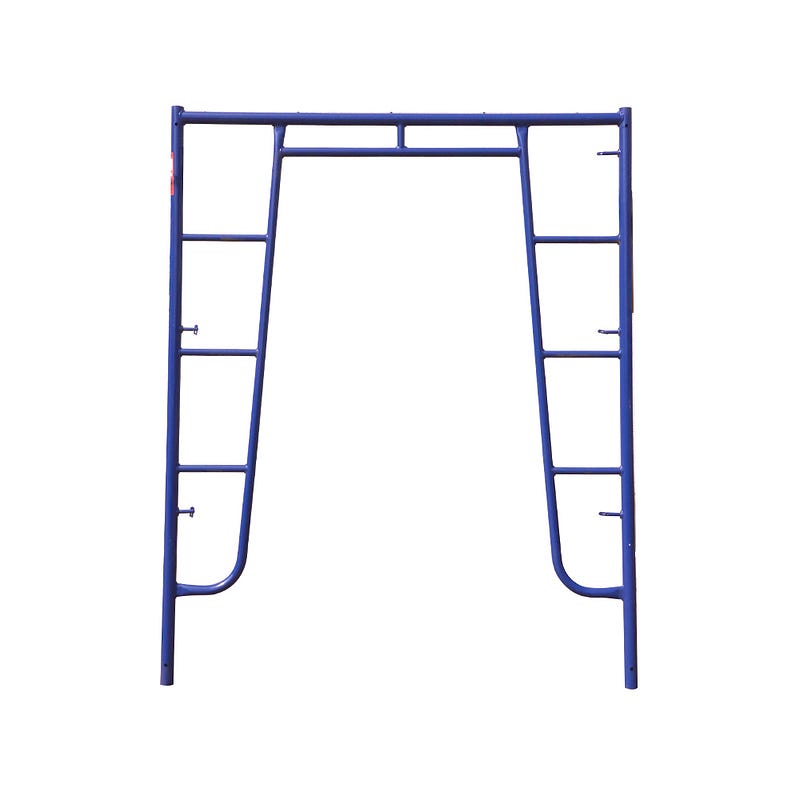

Based on the mechanism used in scaffolding and the types of system, we have Tube and fittings scaffolding, H-frame scaffolding, cuplock scaffolding, and ring lock scaffolding.

Ringlock scaffolding type is also called ring scaffold or rosette scaffold. The heart of the Ringlock system is the columns with fixed ring connectors, each with 8 punched holes. It is now possible to hook up to 8 bars and diagonals into them and fix them with a hammer. This is much faster than the usual ratchet. The ringlock scaffold is considered to be the most modern, versatile, and capable scaffolding system in terms of its load-bearing strength. The different components used in ring-lock scaffolding are multiple ledgers, clamps, guardrails, connectors, stair longitudinal beams, steps, and adapters.

Use cases for the ringlock scaffold

With the ringlock scaffold, you have a great deal of angular flexibility. This makes it ideal for objects with complex shapes — and consisting of a small number of basic components. As a result, you can use this type of ringlock scaffold for a wide range of projects in different sectors. Here are some examples

Building construction

Infrastructure projects such as bridge construction and maintenance

Shipbuilding and repair

Mining industry

Oil refineries and chemical plants

Offshore projects such as wind farms, oil rigs, or natural oil platforms

Event technology such as grandstands

To be able to meet the requirements of these applications, ring-lock scaffolding is particularly resistant to corrosion, for example due to galvanized steel.

5 reasons for using ringlock scaffold

1) Ringlock scaffold offers a higher degree of flexibility to lock different numbers of angles and to align exactly 45 o / 90 o using grooves. Using the ringlock scaffold is also particularly sustainable for you.

2) The ringlock scaffold offers up to 8 connections in a unique garland arrangement present in different system segments, which can be self-locking using a hammer by means of an adaptive wedge. This is particularly easy and quick due to the flat shape of the garland connectors. ringlock scaffold not only allows for quick assembly and disassembly but also space-saving storage

3) Ringlock scaffold offers best-in-class frame body stability with complete vertical bar, bar, horizontal diagonal and vertical diagonal structural support in 3D space, providing a complete lattice system. Thanks to the prefabricated ringlock scaffold attachment points, ringlock scaffold is less prone to errors than conventional pipe clamp scaffolding. As a result, you can easily obtain safe scaffolding.

4) The commonly used ringlock scaffold material is cold galvanized or hot dip galvanized, using anti-corrosion technology to ensure the longevity and reliability of the components. You don’t have to worry about your ringlock scaffold even if conditions on the construction site get a little rough. scaffold materials are hot-dipped galvanized and are therefore particularly durable and resistant to environmental influences, and have a particularly high load-bearing capacity.

5) Ringlock scaffold can be assembled quickly and easily with fewer set-up components and is thus easy to store and transport. one of the core advantages of the ringlock scaffold type is the fast set-up and dismantling time. The ledger and diagonal can be fixed to the ring connector with just a few hammer blows. This saves not only time but also manpower. This applies not only to ringlock scaffold assembly and disassembly but also to maintenance tasks such as cleaning materials.

In addition to these reasons, the load-bearing capacity of the ringlock scaffold has proven to be superior to similar products. the flexibility and options offered by the geometry of the ringlock scaffold are not only unique but also support many different build types through plate formwork, bridge formwork, etc.

Scaffolding is an integral part of our building, construction, and associated maintenance work. Choosing the right type of scaffolding is, therefore, necessary not only for safer work at height but also for reducing construction times.

The storage and transport of scaffolding materials can cause delays, especially on large construction sites, and ringlock scaffolds can help to reduce such problems. Faster installation times can also save on labor costs. And longevity means they enjoy a longer life span, which increases reusability. This further helps to control the cost of purchasing new scaffolding materials, especially in intensive operations.

Ringlock scaffold has established itself in the global market as one of the most commonly used modular scaffolds. Find out more about our ring lock scaffold in our product brochure.

The above article is taken from the news page of ZHONGHONG, if you want to know more, you can click here.

Previous: Introduction of Space Frame Structure

Next: Fiberglass Mesh Reinforcing and Bonding Cement, Roofing Tiles, Mosaic and Various Building Materials

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used