BAPV vs BIPV: What’s the difference?

For several years now, equipping buildings with photovoltaic modules has been more than just installing solar installations on existing roofs. It is now possible to integrate PV installations as a completely separate architectural element at the design stage of a building, thus maximizing the aesthetic quality of the building project.

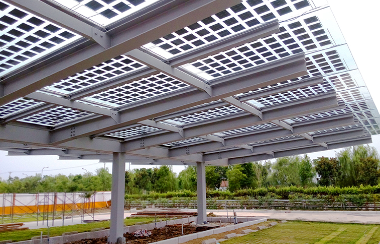

The common feature of these two integrated solar installation technologies is their use in the building sector. In both cases the objective is to enliven surfaces, including sloping and flat roofs (tiles, metal sheets and waterproof membranes), facades, sunshades, parapets and skylights.

The main differences between BAPV and BIPV are the way they are designed and their integration into the building in question.

The BAPV (Building Applied Photovoltaic) approach involves the installation of modules onto existing surfaces by stacking them after the building has been completed, for example in an energy retrofit project. This is the method used for conventional PV solutions.

The BIPV (Building Integrated Photovoltaic) method involves replacing conventional building elements with materials containing solar modules. This provides the dual function of producing energy and providing an architectural element for the finished building. The second technique can be employed at any time, from the outset or during a building project, or afterwards when a part of the building is refurbished (roof, windows, cladding, etc.). This is the most popular method when designing “movable” building products.

The European regulation covering building products (CPR 305/2011) sets out seven basic requirements applicable to building projects to assess performance (energy efficiency and insulation; mechanical resistance and stability; fire safety; hygiene, health and environment; safety and accessibility in use; noise protection; sustainable use of natural resources). It was therefore decided that the use of photovoltaic modules would improve energy performance — even more so if the BIPV approach is used, thanks to the technology’s dual function.

In urban areas, the use of building roof surfaces alone is still limited, as there is often a preference for taller buildings on smaller plots of land for reasons of space constraints. Terraces are increasingly becoming favored social areas, leaving even less space for technical equipment. It is therefore ideal to opt for the integration of equipment that can be used on as many available surfaces as possible and is easy to install. Finally, in urban areas where maintaining the aesthetic quality of the space is an important issue, BIPVs also have the advantage of making the presence of PV modules more invisible. Given these objectives, the BIPV integration approach is increasingly becoming the ideal solution for applications in urban areas.

The thin film has been designed to be integrated into all elements of the building facade and roof. Its high sensitivity to diffuse light allows it to produce optimum results in different directions, just as it does on building facades. It is also capable of producing energy at low light levels. This means that the daily production capacity is 10 to 20 percent higher than that of silicon-based PV technology for the same installed power level.

It has an ultra-flexible 2.5 cm radius of curvature, which means it can tightly adhere to the surface of the application. This is suitable, for example, for covering metal fabric structures in certain sports stadiums and shade structures in car parks. Roll and unroll tests have also confirmed its ability to be applied to winding systems such as blinds.

An important difference from other technologies is their translucency. It currently has a light transmission rate of 30% and we are aiming for 60%. This will allow us to combine energy production with a shading function — a major problem with all exposed glass curtain walls. This dual function will promote energy savings in air conditioning systems.

Photovoltaic technology is versatile and can be integrated into materials as well as superimposed on the roof of a building, for example. We are now developing “ready-to-adhere” photovoltaic modules that are compatible with metal, glass, polycarbonate, etc. These films can be installed quickly and easily; thanks to their light weight, they can be easily rolled and unrolled by one person without taking up much time. These “ready-to-adhere” modules represent the ideal solution for all building energy retrofit projects and for all existing buildings that are not designed to take on additional loads.

At the same time, we are developing partnerships with companies in the construction industry to incorporate the film in the production phase. The aesthetic aspect and the use in future “smart” facades will play a leading role in these new “active” building materials specified by the architects.

It is important for planners and customers to establish a programme that promotes or favours the use of innovative low carbon PV solutions. The message is therefore initially addressed to them. Subsequently, the developer, builder and then the architectural and engineering team must include it in their submission or proposal. This requires contact with our team at an early stage of the project. In terms of the operation of construction and renovation projects, the earlier we are involved in the project (from the first architect’s drawings), the more the solarisation potential of the building can be optimised. Our manufacturing department can help the project manager to select the most suitable substrate and application for the desired result.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used