The portable pipe beveler is a heavy-duty machine for perfect welding preparation with high precision. The portable pipe beveler is fixed to the workpiece by an internal or external clamping mechanism. It is operated by the welder, who manually feeds the pipe beveler using a lever, ratchet or rotary grid. Two or more tools are fixed to the tool holder. The speed is adjustable, depending on the material, wall thickness and diameter.

Why use a portable pipe beveling machine?

1. To create the perfect bevel

All portable pipe beveling machines are equipped with electric or pneumatic drive. Thanks to the aluminum housing, the machines are very light and compact, making it easy to prepare thick-walled pipes with high wall thicknesses on site. There are great areas of application and special tools available. Orbital welding also requires pipe edge preparation for optimal weld edge preparation by external and internal beveling. Preparation of alloy pipes is also possible. 2.

2. Optimum preparation of heavy pipes

Joint preparation for heavy-duty pipe bevels is used for pipe weld edge preparation in many industries. For materials such as duplex, boiler steel and stainless steel, these special tools can be used to create perfect bevels. Dedicated portable pipe bevelers for weld preparation are used in the power supply industry, industrial process industries, boiler manufacturing, shipyards, refineries and chemical processing industries. Our portable pipe cutting bevelers are the best way to prepare pipes for perfect welds.

3. The fastest and safest way for portable pipe beveling machine

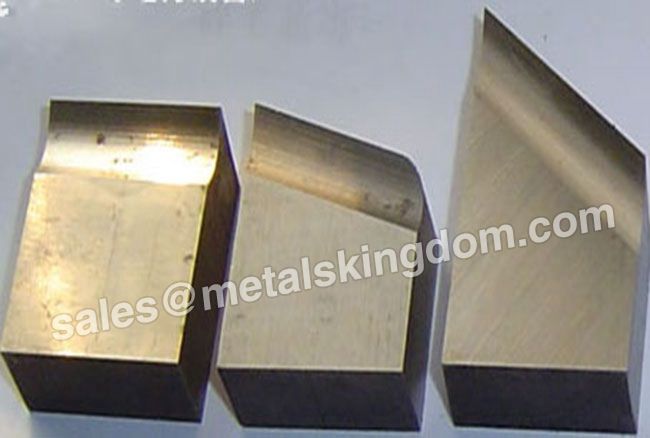

Usually, for pipe edge preparation of thick-walled pipes, the welded edges must be beveled in the V-prep, J-prep, end face or countersunk hole. Most companies use a heavy-duty grinder to do this work. This takes a long time, is imprecise, and can create harsh working conditions for workers. Dust, vibration and noise can cause welders to become ill. Poor quality weld preparation can reduce the quality of welded connections and long working hours can increase production costs.

Top 10 uses/advantages of portable pipe beveling machines

1. By using a portable machine, you can avoid dangerous operations such as hand grinding or torching.

2. You can get consistent and accurate pipe bevels every time you use the machine because its cycle time is usually in the range of 5 to 20 seconds. It can also vary depending on its size.

3. It also eliminates any ergonomic problems that usually come from operators handling hand tools.

4. It is a safer alternative to hand sanding or torching because all the dangerous variables are contained within the machine.

5. The low operating and maintenance costs make it a more cost effective option.

6. It can bevel materials such as stainless steel that are not suitable for torching.

7. It is very easy to use, so even unskilled operators can use this setup.

8. It comes in several variants so you can easily find the one that meets your needs.

9. By using these portable machines, the biggest benefit you will enjoy is that they are mobile, easy to use and time saving.

10. Since the operator can bring the machine itself to the pipe, it ultimately makes the workforce more flexible and efficient.

Previous: What Is a CNC Lathe?

Next: Most Advanced Medium Speed CNC Wire Cut EDM Machine From Sanxing Machinery

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used