What are the main types of synchronous motors?

Synchronous generators are over a hundred years old. The real beginning was in the 1880s. First, fixed poles were used, with the poles surrounding a rotating ring armature. This was called the outer pole type. An important milestone was the "three-phase generator" derived from a DC motor with a Thomson-Houston armature. The three armature coils and their common internal neutral no longer carry a three-stage commutator, but are on three slip rings. The reversal of this structure, i.e. the internal pole type with rotating field and stationary armature, was also considered as a possible form and was subsequently studied. It was soon seen that the best value was to be found by combining the three phases to form the so-called 'rotating current system' of the transformed AC system. These machines were equipped with 'triple-coil pairs' in the armature, whose inner ends were star-shaped connections and whose outer ends were simply connected to three 'long-distance' transmission lines. Hasselwand is credited with identifying the rotating currents in the function of synchronous motors, and he was the first to attempt this in practice. 1887 he built the first three-phase synchronous generator, which produced a power of about 2.8 kW 960 revolutions per minute, corresponding to a frequency of 32 cycles per second, today known as Hertz, or Hz. This machine had a stationary, toroidal, three-phase armature and a rotating "inner pole magnet" with four wound convex poles, which provided the rotating field. 1891 was the year when the three-phase synchronous motor made its real breakthrough with the first big test. This is when the synchronous generator was born. Synchronous motors have always been the most important electromechanical power converters, playing a key role in the production of electricity and in certain special drive applications. But it comes in a wide variety of types.

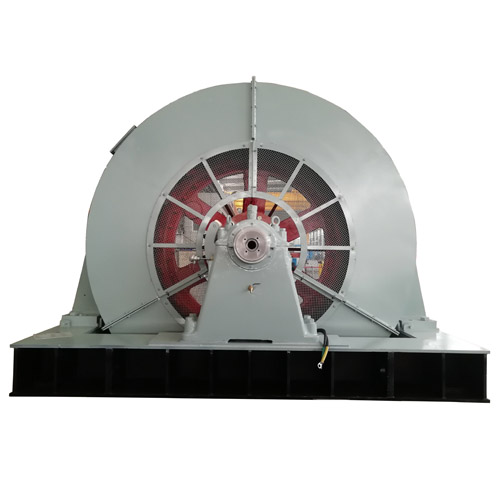

Different types of synchronous motors:

Depending on the method of magnetisation of the rotor, there are two types of synchronous motors.

Unexcited motors

DC-excited motors

In this type of motor, the rotor is magnetised by an external stator field and the rotor has a constant magnetic field. In this type, high retention steels, such as cobalt steel, are used in order to manufacture the rotor. This leads to three other classifications, namely permanent magnet motors, reluctance motors and hysteresis motors. For the design of permanent magnet synchronous motors, permanent magnets are used together with steel. They have a constant magnetic field in the rotor, so that the induction winding cannot be used for starting. Used as a gearless lift motor. The rotor of reluctance motors is made of cast steel parts with projecting magnetic poles. The rotor poles are smaller than the stator poles to minimise torque pulsation. Hysteresis motors are self-starting motors. In this type of synchronous motor, the rotor is a smooth cylinder made of hard cobalt steel. This type of motor is expensive and is usually used where a precise constant speed is required.

In this article we first show you where synchronous motors are produced. Secondly, we describe the types of synchronous motors according to which they are classified. Finally, if you want to find out more about them, you can click here.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used