If you use a lot of packaging, you're probably familiar with corrugated cardboard. But do you know the factors that determine the strength or price of corrugated cardboard? What is it made of? How does this affect the success of your packaging? This guide is intended to explain and clarify information you may need to know about the terminology used in paperboard. 3/5/7 Ply Corrugated Cardboard Production Line supplier shows you.

Material Composition

A standard corrugated board is actually made from 3 components. These are the middle sheet of corrugated or "fluted" material, which is placed between two layers of paper - the outer and inner liners.

During the manufacturing process, each side of the fluting material is glued to a flat paper liner. The glue holds the grooves in place and adds rigidity and stability to the paper.

Paper Type

One of the key factors in determining the characteristics of corrugated materials is the type of paper used. Although paperboard is widely used, there are two main types of paper commonly used for lining. These are referred to as kraft paper and test liner.

Kraft paper is made from the cork tree. Because of the "virgin" fibers, it is both the strongest type of paper and the easiest to print on. For this reason, it is the most commonly used outer liner when selecting materials for the production of corrugated boxes and packaging.

Paper Weight GSM

Once you know the types of paper available and commonly used, it is also important to consider the weight of the paper. Virtually all paper is measured the same way, and the term gsm stands for Grams per Square Meter.

Essentially, if you take a square meter of paper and weigh it, you will get the number of grams per square meter (i.e., the weight). So if you are using corrugated board with a 125 gsm kraft liner, you will typically see it referred to as 125K.

Wall Type

At the basic level, corrugated board consists of two liners and a groove. This is called a "single wall" board. However, additional fluted sections and additional liners can be added to create what is called a "double wall" or "double wall" material. This effectively adds extra stiffness and strength, making it suitable for packing heavier items and adding extra protection for items that may be more delicate or expensive.

Finally, if you are shipping particularly heavy or large items (e.g., automotive parts, industrial equipment, etc.), then a "triple wall" grade can also be used. As the name implies, this adds another section of grooves and additional lining.

Flute

The last aspect of corrugated board that can affect its performance (as well as weight and cost) is the flute type.

The flute is the "corrugated" part between the two liners, and by varying its height (and the size of the flute), different performance characteristics can be obtained. The flute itself is usually made of waste-based flutes or so-called semi-chemical flutes.

E flutes

E flutes are approximately 1 mm to 1.5 mm thick and offer very fine flutes. This not only gives it excellent compressive and compression strength, but also means that it provides a high quality surface for printing. As such, it is commonly used for smaller cartons where high quality printing is required, as well as for die-cutting applications.

B Flute

B Flute is one of the most commonly used paperboard types for packaging applications. With a thickness of 3 mm, it is versatile and can be used in die-cutting and conventional shell making processes. It has good all-around performance in all types of packaging.

C Flute

With a thickness between 3.5 mm and 4 mm, C flute has a greater compressive strength than B flute. This means that it provides better stacking strength when used for lightweight products. However, it can be easily crushed if used in the wrong application.

BC Flute

This double-walled material is 6 mm to 7 mm thick and combines B- and C-slots. This provides good all-around performance and has made it common in the production of shipping boxes that offer a higher level of transport protection. As a result, only basic printing is often added.

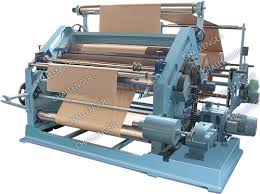

The cardboard production line consists of hydraulic mill roll stand, bridge, automatic aligning machine, pre-heater, pasting machine, pressing machine, heating and cooling machine, slitting machine, Nc cutting machine and automatic cardboard stacker. Our cardboard production line is advanced, easy to operate and has the feature of energy saving.

Previous: The Best Reasons to buy Pulp Molding Machinery

Next: Hot sale pv solar bracket tapping punching and cutting machine

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used