With the rapid development of the manufacturing industry, offshore oil and gas, petrochemical, coal chemical, heavy high-pressure vessel products are becoming more and more popular, thousand-ton hydrogenation reactor, two thousand-ton coal liquefaction reactor is widely used, so that heavy rolling thick plate and high-strength plate of special rolls become key equipment.

Rolling machine, also called rounding machine and roller machine, is a general forming equipment for rolling metal plates into cylindrical, conical and curved shapes.

According to the principle of three-point forming circle, the relative position change and rotational movement of working rollers make the metal sheet produce continuous plastic deformation, so as to obtain the workpiece of predetermined shape.

It is widely used in boiler, shipbuilding, petroleum, chemical, metal structure and machinery manufacturing industries.

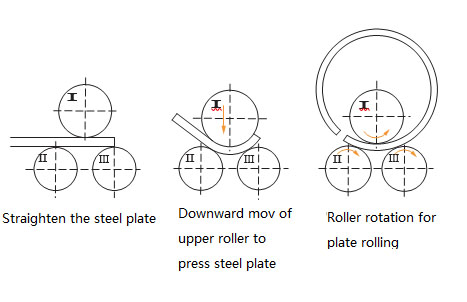

As shown in the figure below, the three-roller plate rolling machine usually takes two lower rollers as the active rollers, which can realize forward and reverse rotation. One upper roller is the driven roller, which can move up and down vertically.

When rolling the sheet metal, the plate is placed between the upper and lower rollers, and the plate can be bent into an arc or closed circle through the three cutting points exposed on the sheet metal by the three rollers.

Therefore, the forming process of sheet metal can be regarded as a continuous three-point bending process performed by a three-roller bending machine.

In the process, one end of the sheet metal is fed into the three-roller plate between the upper and lower rollers, and then the upper rollers displace the sheet metal downward, causing a certain plastic bending deformation of the plate below it due to compression.

When the rollers rotate, there is friction between the plate and the rollers, so when the rollers rotate, the plate also moves along its longitudinal direction.

The lower roller alternates forward and reverse rotation, the roll plate moves back and forth, the two lower rollers rotate, and the friction drives the plate and the rollers to move.

At the same time, the upper roller continues to exert downward pressure on the roll, and the upper roller moves back and forth on the plate.

When the plate passes through the bottom of the upper roll in turn (roll deformation zone), the stress exceeds the yield limit, plastic deformation will occur, and the plate gets plastic bending deformation along its full length and is processed into the required shape.

Proper adjustment of the relative position of the upper and lower rollers, the plate can be bent to a radius not less than the radius of the upper rollers.

The following is the working principle diagram of the symmetrical three-roller plate rolling machine.

The driven rollers II and III are driven by motor and reducer and rotate in the same direction and at the same speed (or in the opposite direction).

Due to the friction between the roller and the plate, the plate is driven forward and the roller rotates.

Appropriate adjustment of the upper roller position can make rolls of different curvature plates.

If the workpiece cannot reach the required curvature after rolling processing, the upper roller can be lowered appropriately and then reverse rolling can be repeatedly performed until it is rolled into the required shape.

As can be seen from the above diagram, the three rolls of the symmetrical three-roller bending machine are arranged in an isosceles triangle, so the two ends of the workpiece are bound to leave a straight line during the rolling process.

The length of the straight segment is about half of the distance between the centers of the two lower rollers. This part of the straight line is where the rollers cannot roll, which is the biggest drawback of symmetrical three-roller rollers.

Despite the disadvantages of the symmetrical three-roller rolling machine, but because of its simple structure, easy operation, low cost and widely used.

Previous: What are the advantages of continuous inkjet printers?

Next: What Should I Pay Attention to in the Use of a CNC Lathe Machine?

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used