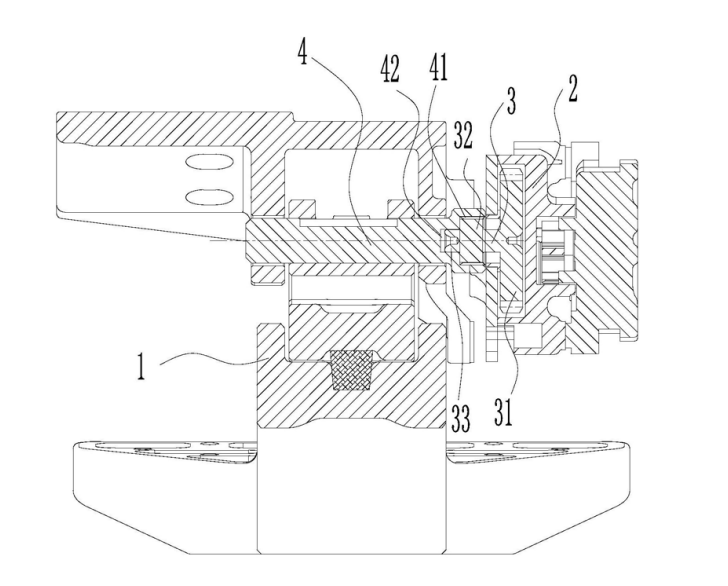

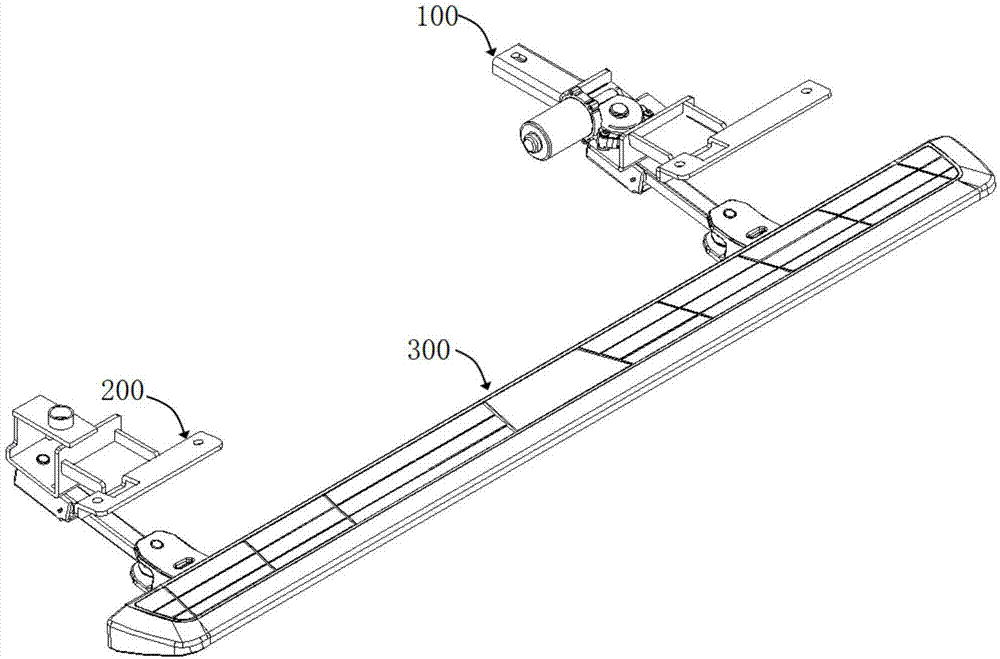

This article discloses an automobile electric pedal telescoping mechanism, including a pedal telescoping assembly, a motor reducer assembly and an output gear shaft. The output gear shaft is provided with an output gear and a connecting key. The output gear is connected with the motor reducer assembly and also includes a connecting shaft , The connecting shaft is connected with the pedal telescopic assembly; the connecting key is set as an external spline, the connecting shaft is provided with an internal spline, and the external spline and the internal spline cooperate to connect the output gear shaft and the connecting shaft. The spline connection replaces the connection method in the prior art in which a long output gear shaft is directly connected to the pedal telescopic assembly, which can reduce the processing accuracy and positioning accuracy of the relevant parts of the pedal telescopic assembly and the motor reducer assembly; Avoid wear and tear of the output gear shaft and shaft hole after a long time of use, which may cause uncoordinated movement of the pedal, thereby reducing noise during operation; in addition, the spline connection can be automatically separated during disassembly, which is convenient for disassembly and maintenance.

Auto electric pedal is a kind of pedal that can automatically extend and contract, which provides convenient services for the convenience of up and down of high-chassis cars. When the door is opened, the electric pedal automatically extends, and the pedal stops when it reaches the limit position; when the door is closed, the electric pedal automatically retracts, and the pedal retracts to the bottom of the vehicle.

The auto electric pedal telescopic mechanism includes a pedal telescopic component and a motor reducer component. At present, the motor reducer assembly transmits torque to the pedal telescopic assembly through the output gear shaft of the reducer, that is, one end of the output gear shaft is connected to the motor reducer assembly, and the other end is connected to the pedal telescopic assembly, so the motor reducer assembly and the pedal telescopic assembly form one Rigid whole. To ensure the flexible operation of the two major components of the pedal telescopic assembly and the motor reducer assembly, reduce the motor load and reduce the overall noise, it is necessary to improve the assembly accuracy of the pedal telescopic assembly and the motor reducer assembly and the processing accuracy of the parts used , Such as: improve the coaxiality of the output gear shaft and the shaft hole of the telescopic mechanism; improve the verticality and flatness of the positioning reference; due to the limited level of the existing technology and the accumulated errors in the assembly process, the motor reducer components and The pedal telescopic components cannot be coaxial, and the output gear shaft is a rigid whole. In this way, after the car pedal is used for a period of time, the shaft and the shaft hole will be severely worn. At this time, the car pedal telescopic mechanism will experience uneven operation and noise Especially big problems.

WOKRING PRINCIPLE

The motor reducer assembly 2 drives the output gear shaft 3 to rotate. The output gear shaft 3 is connected to the connecting shaft 4 through the cooperation of external splines and internal splines and drives the connecting shaft 4 to rotate. The connecting shaft 4 drives the pedal telescopic assembly 1 to rotate. The spline connection replaces the integral connection method in which a long output gear shaft is directly connected to the pedal telescopic assembly in the prior art, which can reduce the processing accuracy and positioning accuracy of the relevant parts of the pedal telescopic assembly and the motor reducer assembly; At the same time, it can avoid the wear of the output gear shaft and shaft hole after long-term use, which will cause the uncoordinated movement of the pedal to reduce the noise generated by the resonance of the output gear shaft and the housing during operation; in addition, the spline connection can be automatically removed during disassembly. Separation, the disassembly can be quickly completed without disassembling the entire set of automobile electric pedal telescopic mechanism, which is convenient for disassembly and maintenance.

The beneficial effect of this article is that the spline connection replaces the integral connection method in which a long output gear shaft is directly connected to the pedal telescopic assembly in the prior art, which can reduce the cost of the pedal telescopic assembly and the related parts of the motor reducer assembly. Machining accuracy and positioning accuracy; at the same time, it can avoid the wear of the output gear shaft and shaft hole after long-term use, which will cause the uncoordinated movement of the pedal to reduce the noise caused by the resonance of the output gear shaft and the housing during operation; in addition, the spline The connection can be automatically separated during disassembly, and the disassembly can be completed quickly without disassembling the entire car electric pedal telescopic mechanism, which is convenient for disassembly and maintenance.

Previous: The Tips for Car Airbag Repair

Next: None.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used