In the application process of various buried pipelines, whether the pipeline can achieve the specified long-term service life is a key factor

Element is the quality of laying. The multiple unique properties of Hdpe Water Pipe make the laying of pipes more diversified, and at the same time correct

The construction design and installation procedures of the company will make these superior performances of the pipeline be brought into full play to a greater extent.

1. Technical preparation before construction

A. Be familiar with and master the construction drawings before construction;

c. Prepare the corresponding construction equipment;

C. Carry out induction training for operating workers, and construction can only be carried out after the training is qualified.

D. Acceptance of pipes and fittings in accordance with standards.

2. Excavation of pipe trench

The excavation of the pipe trench must be carried out in strict accordance with the excavation route and excavation depth guided by the design drawings or engineering supervision

construction

Hdpe Water Pipe has good flexibility and light weight,

Therefore, there are straight pipe and reel types.

It is better to choose straight pipes for convenient construction in places where more welded pipes are densely packed.

For long-distance, you can choose the HOPE tube of the coil

In order to reduce the number of welding.

The excavation width of the pipe trench is determined by the construction space of the pipeline, so it is recommended to choose a pipe for short and straight pipeline construction.

External welding of the trench reduces the excavation area.

3. Preparation of the bottom of the pipe trench

For pressure systems like water supply, sewage or long-distance transmission pipelines, unless the design drawings have special requirements, one

Generally speaking, the horizontal accuracy requirements of the bottom of the pipe trench are not very high. For gravity drainage systems, the grade of slope must be

Meet the specified requirements. According to the construction requirements, the excavated bottom of the trench should be at least 150mm deeper than the specified level.

Then backfill and compact with appropriate landfill materials, and then pave the sand layer with a thickness of ≤100mm to achieve the required pipe burying

deep.

4. HDP pipe Water welding

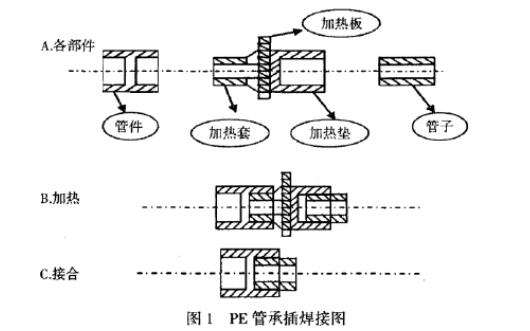

A Electrofusion socket welding

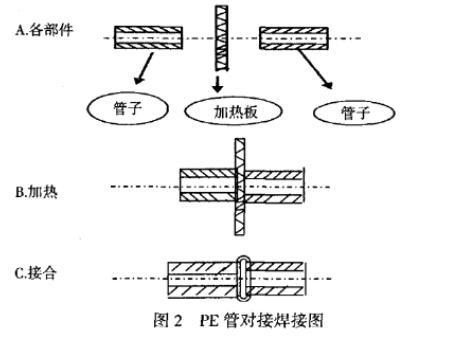

B Butt welding

5. Pressure test of Hdpe Water Pipe

The HDPE piping system should be pressure tested before being put into operation. Pressure test includes strength test and water tightness test

Two things. It is generally recommended to use water as the test medium during testing. The strength test is to eliminate the voids in the pipeline to be tested.

After the gas is released, increase the pressure to the required pressure value at a steady pressure increase rate. The pressure gauge should be placed as far as possible in the pipeline

Lowest point. The pressure test should be performed before the pipeline is backfilled. During the pressure test, the pipe should be fixed in place, all fittings

Connection parts, flanges, etc. should be exposed to facilitate checking for leaks.

The test pressure of the pressure test should not exceed the pressure rating of the pipe or the pressure rating of the accessories with the lowest pressure rating in the system

At the beginning, the pressure should be raised to the specified test pressure value and stay for enough time to ensure that the pipe is fully expanded.

When the system pressure reaches the required pressure value and stabilizes, check the pressure value again after 2 hours of stabilizing pressure. During the pressure test,

Because the continuous expansion of the pipe will cause a pressure drop, it is normal to produce a certain pressure drop during the test, and it cannot

Therefore, to prove that the pipeline system must be leaking or damaged.

Water tightness test HDPE pipes are connected by electric heating, which makes HDPE pipes more superior than traditional pipes

The watertight performance. The test pressure of the water tightness test should not exceed the pressure rating of the pipe or the fittings with the lowest pressure rating in the system.

1.15 times the pressure rating. When the pipeline pressure reaches the test pressure, it should be maintained for a certain period of time to allow the temperature of the test medium in the pipeline

When the temperature and pressure are stable, start timing. Under normal circumstances, the water tightness test should be stabilized for 24 hours. After the test, if there is no obvious leakage or pressure drop, the water tightness test should be passed.

5. Fix and backfill. After the pressure test is completed, it is necessary to use concrete to make fixed piles to ensure that the welding fittings of the HDPE pipe will not be displaced due to the pressure in the pipe or the surrounding geological environment and cause water leakage in the future use.

Previous: Black & Grey Fiberglass Window Screens

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used