In today's market, there are many types of filling machines for packaging various products, including liquid, paste, block products, powder, granules, tablets, capsules and so on.

At present, people are most concerned about the medical and health issues, we wrote an article dedicated to capsule filling equipment - what is capsule filling equipment?

In the filling machine category, there are usually many choices, so we always encourage you to call or send us an email to solve problems in the selection process. This article will introduce the types of liquid filling machines and the main steps to find a suitable liquid filling machine.

Liquid filling machine usually use pressure overflow filling machines, which have very fast filling speeds and can handle a variety of viscosities. All residual product in the filling tube will be pushed back into the storage tank to prevent spills and spills.

Desktop filling machines, semi-automatic filling machines and fully automatic filling machines all need to use a pump for each filling head. The pump helps the liquid pass through the product channel and into the waiting container, making the machine a good solution for handling dense or free-flowing liquids.

Let’s start!

So you want to buy a liquid filling machine, what exactly do you want to pack with it?

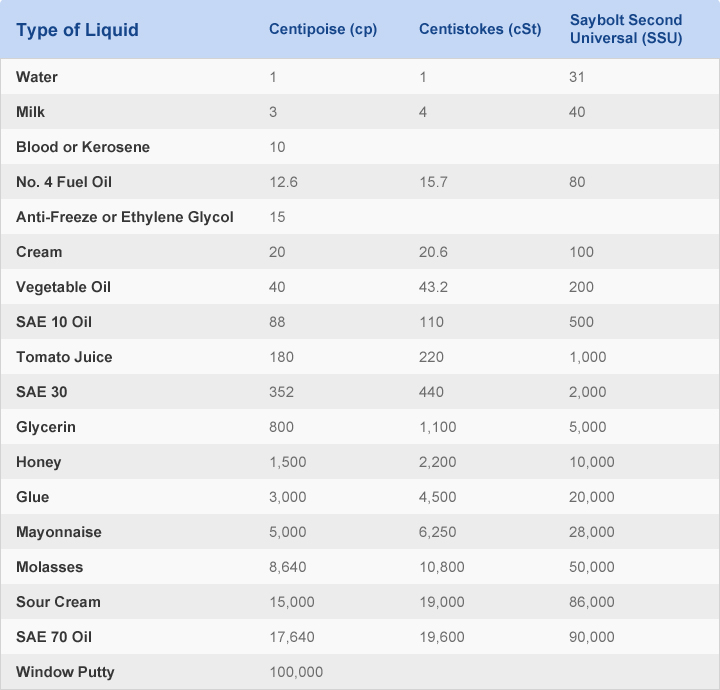

Think about it, is there difference when we use a filling machine to handle with water and molasses? The result is obvious. If your product has a high viscosity, you need to consider buying a filling machine that can handle the physical properties of the item. Therefore, the requirements for filling machines are different for filling low-viscosity and high-viscosity products.

Here is a viscosity chart.

There is Carbonated Beverage Bottle Fillers for carbonated beverages like beer, soda or champagne. you'll need to consider purchasing a counter pressure fillers.

What material is it made of? Plastic, glass or aluminum each requires its own specific filling technology. Knowing which material to use will help determine which filling machine to buy.

The shape of the container also affects the most suitable machine. For example, your container has a non-standard lid or cap, an automatic bottle filling machine that grabs the bottle from the top may not be the best choice.

First, we need to figure out one question: The faster the better?

It depends on the situation.

Very productive companies may benefit from the most efficient machines.

Smaller companies may sacrifice some speed to save cost and space.

The speed of a small machine is measured by the bottles produced per hour (BPH). The speed of larger, more efficient filling machines is measured in bottles per minute (BPM).

So this is a hint: When buying a filling machine, please be careful not to ignore your future production needs.

Manual filling machines are designed to handle low productivity, and they are an economical and space-saving option for hobbyists or small companies that do not plan to expand.

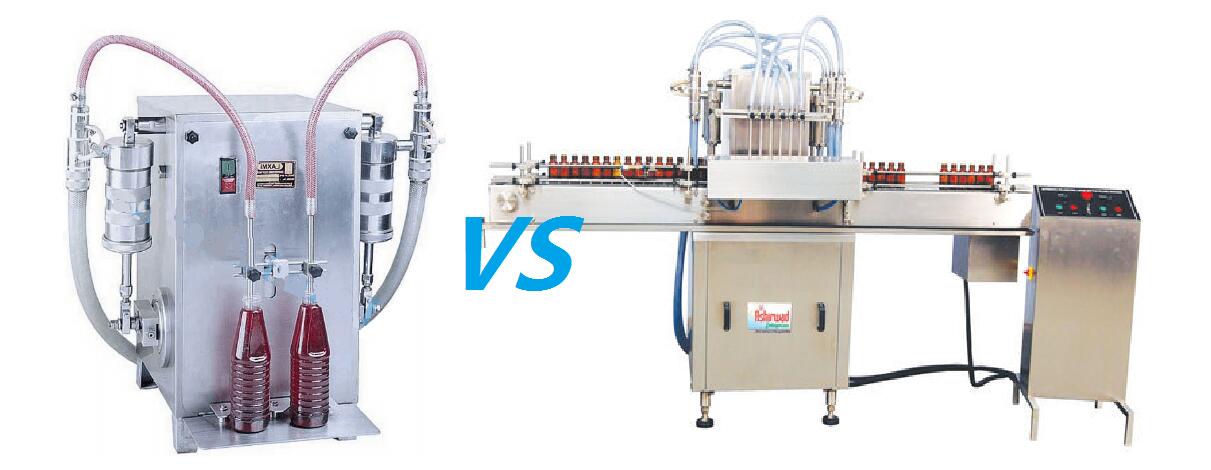

Semi-automatic filling machines can produce bottles much faster than manual filling machines, but they still require some manual operations. These machines will not reach the exact same speed as the fully automatic filling machine. However, their mid-range prices generally make them the best choice for small and medium-sized enterprises that do not yet need the largest system but still have development plans.

The automatic filling machine is the driving force of production, which is very suitable for large companies with high production efficiency. These machines use conveyor belts to pull bottles from the bulk warehouse. They require the largest footprint, and their purchase and maintenance costs are higher than manual or semi-automatic filling machines. However, they do not require manual operation or require very little manual operation to run.

I wrote an article about Automated vs. Semi-automated and Manual before, you can take a look, here are more detailed differences.

Which type of liquid filling system is best for you?

Ultimately, the type of filling machine you choose should be based on two key pieces of information: the type of product you will use to fill the container, and how you want the final filling level in the bottle to appear.

All filling machine systems fall into one of these two categories: liquid-level or volumetric.

Liquid filling machines are important equipment in various industries, such as cosmetics, pharmaceuticals, food and beverage industries, where liquids will be packaged in various types of containers. Pump filling machines, whether bench-top, semi-automatic or fully automatic, use a pump for each filling head on the machine. The pump helps move the liquid through the product channel and into the waiting container, making the machine a good solution for handling thicker or poorly flowing liquids.

The automatic volumetric liquid bottle filling machine uses a submersible nozzle to work according to the volume principle. The double pneumatic stopper system and the reciprocating nozzle can accurately match the jogging of the container under the nozzle to avoid liquid splashing on the container.

The volumetric liquid bottle filling machine also requires special instruments for balancing, calibration, and timing, so the overall cost of these machines is higher compared to liquid filling machines. If you fill bottles with more expensive products or products that require precise dosages, the accuracy of volumetric liquid filling machine combined with their versatility in various products can usually save your business a lot of money in the long run.

Inline filling machine can be adjusted to fill a variety of different container sizes without any additional costs due to replacement parts, and is often used/favored by small and medium-sized companies because they can cause any problems in the production process or machine problems.

Rotary filling machine are larger and specialized. These machines can generate much more BPM than ordinary inline filling machines.

Liquid filling machines are precision equipment and are usually a major investment.

When considering a manufacturer, always remember to ask about the following:

Customization ability;

Ability to design turnkey solutions from filling to labeling and everything in between;

Quality review and approval procedures;

Installation process;

Warranty;

on-site support;

Before you make a purchase, if you have anything confused, pls live a comment and we will respond soon.

Previous: What is the Tablet Press Used For?

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used