Stainless steel screen

The stainless steel screen materials mainly include 201, 201, 302, 304, 304L, 316, etc., with the following characteristics:

Good acid resistance, alkali resistance, and corrosion resistance;

High strength, strong tensile force, toughness and abrasion resistance, durable;

High-temperature oxidation resistance, the nominal temperature of 304 stainless steel screen is 800℃, and the nominal temperature of 310S stainless steel screen can reach 1150℃;

Normal temperature processing, that is, easy plastic processing, diversifying the use possibilities of stainless steel screen;

High smoothness, no need for surface treatment, convenient and simple maintenance.

Stainless steel screens are often used for screening and filtering under acid and alkali environmental conditions, as well as mud screens in the petroleum industry, and screens in the chemical and chemical fiber industry.

Welded screen

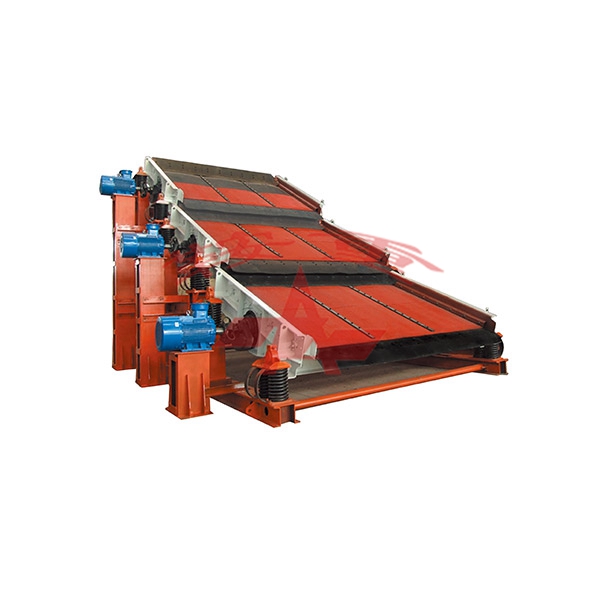

The welded screen is welded from high manganese steel raw materials, the raw materials are the same but the processing technology is quite different. It is separately introduced here because the application of such screens is more common.

High manganese steel has a brittle temperature range for carbide precipitation between 250 and 800 ℃, and as-cast high manganese steel also has network carbides and casting stress, so the welding performance is very poor.

For high manganese steel castings, risers should be cut or defective welding repaired after water toughening treatment, and rapid cooling should be performed after welding. In order to eliminate or minimize the heat-affected zone, apply small current, discontinuous welding, or water cooling while welding. The electrode adopts high manganese steel electrode or austenitic stainless steel electrode. If there is a work-hardened layer, it should be removed before welding.

Perforated screen

Punching screen refers to the screen that uses a punch to punch out the target pattern in the plate to be processed. Generally, it is made of stainless steel, aluminum plate, cold and hot steel plate, copper plate, PVC plate film, and other materials. Holes, square holes, round holes, hexagonal holes, scale holes, stretched shaped holes, etc.

Perforated screens have the characteristics of lightweight, non-slip, beautiful appearance, and good filtering performance. They are often used in environmental protection noise control barriers in traffic and municipal facilities, and mine screens, mine screens, I-shaped screens, etc.

The screen material is a point that many users will emphatically consider when choosing a vibrating screen because it is largely related to the service life of the equipment and the later cost input. Once the selection is inappropriate, it will accelerate the wear of the screen and affect the normal Production increases the cost of parts, so users must pay attention when choosing screen materials, and try to choose products that are wear-resistant and have good results.

The above information is provided by rotary vibrating screen manufacturer.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used